- 5,896

- 3,990

- 113

That directly conflicts with my understanding of it.That is a misleading or confusing way to phrase or think about the problem. The aerodynamic losses make up the smallest contribution, and so even if you could make them totally go away, it would only have a very small effect. However, playing with aerodynamics is way easier to do, compared to changing the efficiency of an engine, especially for laymen.

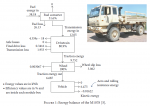

You can look up various studies on the topic, and you will find that the vast majority of wasted energy happens at the engine. I don't remember the exact numbers, but I'll throw out something close (within 5-10%?). The engine wastes 70% of the fuel's power (in other words, for every gallon of fuel you burn, you only get 30% of that energy out as the crankshaft rotating). A further 20% total is wasted by the drivetrain (e.g. transmission friction, axles, etc.). And the last 10% is wasted by the aerodynamics and rolling resistance of the truck.

What this is telling you, is that if you get 5MPG, even if you could make aerodynamics totally go away, you could only gain 10%. In reality, adding big airfoils between the cab and cargo box, or rear "cones", bumps the total MPG by like 1-2%. Fleets do it because that 2% over a million miles driven per year adds up to big savings. One FMTV overlander driving 2000 miles per year, at 5MPG, makes a 4 gallon ($20) difference. (PER YEAR!)

My experience with aero is bicycle related.

At 18mph (IIRC) aerodynamics take over from rolling resistance as the primary impedance. (Bicycles...but should be at least somewhat applicable)

And from firsthand experience on a motorcycle, raising up and catching the wind at 150mph slows you down as briskly as firmly grabbing the brakes...

And one more example - towing a heavy (13k) but dense trailer behind my pickup truck gets substantially better fuel efficiency than towing a relatively light (3200lbs) travel trailer with enormous frontal surface area. I attribute this to aerodynamics.

A quick search on the topic yielded the attached screenshot.

All that being said, I am also of the opinion that tweaking an LMTV based overlanding vehicle for enhanced fuel efficiency is an exercise in futility and not worth the trouble.

Edit to add the complete link of my screenshot -

International Trucks - Fuel Economy Aerodynamics

Fuel Economy Aerodynamics

Attachments

-

82.3 KB Views: 14

Last edited: