- 3,657

- 27

- 48

- Location

- Dallas, Texas

No matter what kind of filter setup, stock, remote spin-on, adapter-mounted, drain or no drainback, guards or no guards..

[][][]

PuraDYN:

In SAE paper #660081 it states, “Filtration of previously used oil to five microns had no significant effect on wear, but filtration to one micron had a substantial effect on wear.”

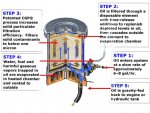

In Stage One, oil enters the unit from a bypass oil pressure line, typically from the oil pressure sending unit or an oil galley plug near the full flow filter. The oil enters the puraDYN® system through a metering jet that limits the flow between 6 to 8 gallons per hour (22 to 30 liters per hour), into a 100% unbleached long-strand natural cotton fiber filled filter element. The solid contaminants, such as carbon, sludge, soot, varnish, dirt, silica, wear metal particles and other foreign matter, are trapped down to 1 micron in size.

In Stage Two the oil, free of solid contaminants, travels into the heated evaporation chamber flowing over a diffuser plate. The oil pressure has dissipated to atmospheric pressure causing the oil to flow in a thin film over the floor and walls of the heated evaporation chamber. The temperature in the evaporation chamber is approximately 200° F but may vary slightly depending on the outside ambient temperature. The heat causes liquid contaminants like fuel, water and engine coolant to vaporize and vent out under their own pressure through the vapor vent out through a vapor vent valve before they can re-condense as would normally occur in an engine not equipped with a puraDYN® system. The cleaned oil is then returned by gravity feed to the engine oil sump.

[][][]

Amsoil:

""

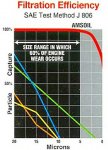

..........the dirt that does the most harm and causes the most wear in an engine is from 5 microns up to 20 microns in size (a human hair is about 100 microns). AMSOIL By-Pass Filters will filter oil to an amazing 1/10 of a micron. ......

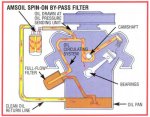

All of the oil passes through the Conventional Filter and then a very small percent of the oil is "bled off" and it passes through the By-Pass Filter. The By-Pass Filter works on the idea of the swimming pool filter... it filters a small amount of the oil at any one time, however, in five minutes, at 45 mph, all of the oil will have gone through the By-Pass Filter.....

A conventional oil filter filters out dirt particles down to about 20 microns. The AMSOIL Spin on oil filter filters out dirt to about 5 microns. If you use the AMSOIL By-Pass system, it will filter out dirt down to 1/10 of a micron.

[][][]

Filtration Systems:

The FS-2500 cleans your oil at an efficiency rate of 2.78 microns absolute. This will allow the end user to extend oil drain intervals dramatically, and most importantly, stop up to 99% of the wear in the engine.

[][][]

Gulf Coast Filters:

AXIAL DEPTH TYPE FILTRATION PROVIDES EFFICIENT PARTICULATE CONTROL OF 1-5 MICRON PARTICLES

EXTENDS FACTORY OIL FILTER SERVICE INTERVALS UP TO 5 TIMES LONGER

MOISTURE REMOVAL DOWN TO 40 PPM

ALL STEEL FILTER HOUSING

NO GASKET REPLACEMENT

NO TOOLS REQUIRED TO SERVICE

U.S.C.G. ACCEPTED

[][][]

sure there are more systems out there..

/\/\/\/

[][][]

PuraDYN:

In SAE paper #660081 it states, “Filtration of previously used oil to five microns had no significant effect on wear, but filtration to one micron had a substantial effect on wear.”

In Stage One, oil enters the unit from a bypass oil pressure line, typically from the oil pressure sending unit or an oil galley plug near the full flow filter. The oil enters the puraDYN® system through a metering jet that limits the flow between 6 to 8 gallons per hour (22 to 30 liters per hour), into a 100% unbleached long-strand natural cotton fiber filled filter element. The solid contaminants, such as carbon, sludge, soot, varnish, dirt, silica, wear metal particles and other foreign matter, are trapped down to 1 micron in size.

In Stage Two the oil, free of solid contaminants, travels into the heated evaporation chamber flowing over a diffuser plate. The oil pressure has dissipated to atmospheric pressure causing the oil to flow in a thin film over the floor and walls of the heated evaporation chamber. The temperature in the evaporation chamber is approximately 200° F but may vary slightly depending on the outside ambient temperature. The heat causes liquid contaminants like fuel, water and engine coolant to vaporize and vent out under their own pressure through the vapor vent out through a vapor vent valve before they can re-condense as would normally occur in an engine not equipped with a puraDYN® system. The cleaned oil is then returned by gravity feed to the engine oil sump.

[][][]

Amsoil:

""

..........the dirt that does the most harm and causes the most wear in an engine is from 5 microns up to 20 microns in size (a human hair is about 100 microns). AMSOIL By-Pass Filters will filter oil to an amazing 1/10 of a micron. ......

All of the oil passes through the Conventional Filter and then a very small percent of the oil is "bled off" and it passes through the By-Pass Filter. The By-Pass Filter works on the idea of the swimming pool filter... it filters a small amount of the oil at any one time, however, in five minutes, at 45 mph, all of the oil will have gone through the By-Pass Filter.....

A conventional oil filter filters out dirt particles down to about 20 microns. The AMSOIL Spin on oil filter filters out dirt to about 5 microns. If you use the AMSOIL By-Pass system, it will filter out dirt down to 1/10 of a micron.

[][][]

Filtration Systems:

The FS-2500 cleans your oil at an efficiency rate of 2.78 microns absolute. This will allow the end user to extend oil drain intervals dramatically, and most importantly, stop up to 99% of the wear in the engine.

[][][]

Gulf Coast Filters:

AXIAL DEPTH TYPE FILTRATION PROVIDES EFFICIENT PARTICULATE CONTROL OF 1-5 MICRON PARTICLES

EXTENDS FACTORY OIL FILTER SERVICE INTERVALS UP TO 5 TIMES LONGER

MOISTURE REMOVAL DOWN TO 40 PPM

ALL STEEL FILTER HOUSING

NO GASKET REPLACEMENT

NO TOOLS REQUIRED TO SERVICE

U.S.C.G. ACCEPTED

[][][]

sure there are more systems out there..

/\/\/\/

Attachments

-

67.5 KB Views: 1,532

-

21.9 KB Views: 1,518

-

103.1 KB Views: 1,518

-

34.8 KB Views: 1,515

-

4.3 KB Views: 1,517