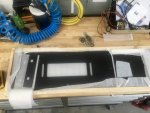

Hard Head, Here's where I was wanting to go with my front install. I've test fit both upside down and rear-ward. I'm not crazy about the fitting as shown below, because it puts the guide plate springs in harms way, and requires a front mount fabrication for the fairlead. But this method

does allow for only a 9" mounting depth (feet mounted rear-ward, pull from top).

Rotate 90, for upside down, and you're ready to go, fairlead in the factory position and with a simple 12" x 15" plate using the factory bolts beneath the radiator frame mount, and the front of the bumper. Downside to that way, is almost 12" mounting height, and need to notch out the inside lower of the front bumper for the control box to fit.

Obviously, either orientation should really have a cage built around it for basic protection.

I'm interested to hear thoughts and design options. Understanding of course that for

my purposes i'm not terribly concerned about approach angle, and I'm not rock crawling, so it's more a matter of stopping road debris.

View attachment 631717View attachment 631716

https://youtu.be/nigB_BhFxbg