- 259

- 23

- 28

- Location

- Sherwood, WI

Gents, I'm not getting power to the ADC100 electric actuator on my MEP-805b, so of course it won't start ... I've read through all of the similar threads that I can find, here and elsewhere on the IntraWebs. Just wondering if my genset problem is obvious to anyone out there. My MEP-805B cranks, but wont' start. I have good fuel pressure all the way to the fuel shut off actuator (ADC100) on top of the injector pump. I did run the test to the fuel shutoff solenoid lead and got correct readings (correct ohms and no continuity). I checked the female side of the fuel solenoid plug (the plug not connected to the ADC100) and got no reading -- nothing -- when cranking the motor. I jumped the fuel solenoid, got he familiar metallic "click", and the motor fired right up. So, what I know is that the generator is not sending the correct signal (no signal actually) to the fuel shut off solenoid. I've done the correct start up procedure, holding the fault switch for two seconds before I crank, so it's not an operator head space and timing issue. The CIM displays no errors, but while booting shows an "Port reads 78 ... Cable disconnected ... " message. I have not yet removed the backplane and done the recommended cleaning, but will do so. Again, just wondering if anyone has had the same issues, with the same "Port reads 78 ... Cable disconnected ... " message … just hoping I can save some time. Thanks much!

Attachments

-

82.8 KB Views: 17

-

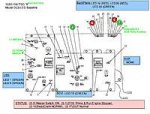

53.4 KB Views: 14

-

42.5 KB Views: 13

-

55.2 KB Views: 12

-

48.6 KB Views: 15

-

88.9 KB Views: 13