I have the fording kit installed on my M813. How long does it normally take for the air system to leak down? Where are the common leak places? Armed with a soapy spray bottle, I started to hunt for leaks . found some. But I am afraid there must be more.

-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Airleaks.. where to look for them m813

- Thread starter 319cssb

- Start date

More options

Who Replied?- 15,815

- 21,957

- 113

- Location

- Burgkunstadt, Germany

My 813 never made it from late afternoon to the next morning. When we parked at COB, say 18:00, next morning at 07:00 the system was empty. Normally we followed the PMCS anyway, and the last thing you did was drain the tanks, so it's hard to say what "normal" time for bleed down is. Having read the TM for the 813 about a million years ago, I do not remember that being listed anywhere. About the only thing we gave thought to was if it held pressure durring on the road time.

- 15,815

- 21,957

- 113

- Location

- Burgkunstadt, Germany

You got problems. Buy another bottle of window cleaner. Take your time. Glad hand valves are a good place to start. Then work toward the tank. Compressor leaks are also a possably.

You only have 2 small tanks on that truck i believe which isn't much air. It would only take an hour for even a non hearable hiss to leak those down. Fix what you can and go from there. Most lines on that truck are metal with inverted flares... Easy way to fix that is to replace the fittings with pipe on the one end and DOT air ends on the other end and add nylon line and the Ferrells to everything and ditch the metal lines.

Good culprit may be the hoses going to the poppets as they are cotton jacket but can leak themselves.

Good culprit may be the hoses going to the poppets as they are cotton jacket but can leak themselves.

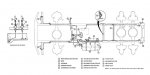

The -p TM is extremely frustrating, if you just try to figure out a setup without knowing what youre looking at.

I found so many air hoses going to all sorts of parts and so few illustrations in the -p.

unimog have a revservoir with alcohol. Is there something like that in the m813?

I found so many air hoses going to all sorts of parts and so few illustrations in the -p.

unimog have a revservoir with alcohol. Is there something like that in the m813?

if you think an 813 has alot of air lines then you should look at a 939 truck. it has more air lines than you have blood vessels. There is a diagramThe -p TM is extremely frustrating, if you just try to figure out a setup without knowing what youre looking at.

I found so many air hoses going to all sorts of parts and so few illustrations in the -p.

unimog have a revservoir with alcohol. Is there something like that in the m813?

Attachments

-

48.7 KB Views: 16

Only 2 lines receive pressure. To the bellhousing and to the air horn when you pull the lever. Should only have air to that pull valve with it shut. Not that much to traceAnd then I have all the valves and lines for the fording kit.

How can I check if the valves are closing properly? I think someone messed with the deep fording cable and just bent the end without the proper adjuster. maybe I got a slow internal leak to the pos pressure system?Only 2 lines receive pressure. To the bellhousing and to the air horn when you pull the lever. Should only have air to that pull valve with it shut. Not that much to trace

You should have no air going to either one of those lines with the valve closed. Pretty simple. If the valve is broke you can get TR1 valve and use it instead. It is a flip switch valve like the deuce and M939 trucks use for the front axle actuation. This would allow air to pass and to those air lines when activated for fording.How can I check if the valves are closing properly? I think someone messed with the deep fording cable and just bent the end without the proper adjuster. maybe I got a slow internal leak to the pos pressure system?

- 7,390

- 2,437

- 113

- Location

- Interlachen Fl.

Yea should not be that hard to trace down air leaks. The way your fording kit is now it shuts off the engine road draft tube and supply's the air with just one pull of the cable. Does your power steering pump have a vent? It needs a water tight filler cap if you do not already have one.

Yes, on the vent, it is connected to the air linesYea should not be that hard to trace down air leaks. The way your fording kit is now it shuts off the engine road draft tube and supply's the air with just one pull of the cable. Does your power steering pump have a vent? It needs a water tight filler cap if you do not already have one.

- 15,815

- 21,957

- 113

- Location

- Burgkunstadt, Germany

One of the reasons the parts manual is confusing is because it covers 4 different types of M813 trucks. What exact model do you have? What parts manual are you using? the -20P? or the -34P? By looking at the parts listing, you can determine what parts fit your model truck, by using the UOC, Usable On Code. So if you look at the picture, and see something that doesn't look like its the same as your model, you can look at the UOC. If its not for your truck, then you can forget it.

You are allowed by DOT to have a leakage rate of 2 psi per minute for a straight truck with the service brake released. So 100 psi could disappear in 50 minutes and be legal. Add 1 pound per minute with service brake applied. An 813 has a somewhat simple air system compared to a 923 or commercial trucks. A cracked copper line or coupling, the governor, the air horn, windshield wiper control valve, stop light switch, low air alarm switch emergency trailer valve or any combination of these can contribute to loss of air poressure. It is more important that the system maintains pressure with the engine running than parked.

- 108,234members

- 163,558threads

- 2,301,475posts

- 1,505online users