martinv

Member

- 50

- 58

- 18

- Location

- Glyndon MN

Here is how it looks now:

My initial question are:

A few more facts:

- July 3: Drove about 36 miles to lake with no problem.

- July 6: Drove about 7 miles and suddenly noticed very excessive smoke out exhaust as I was slowing to make a turn.

- Stopped at gas station to investigate. Among the 1000 normal Deuce sounds, I thought I possibly heard some anomaly in the Turbo but my turbo is not the loud whistler version. I just though i heard a intermittent scraping spinning sound, but this could have been some random panel vibrating...

- At this point there was no oil noticed coming out the exhaust

- Within about 10 minutes a very knowledgeable Deuce owner (Dan) happened to drive by!!

- We noticed the oil level seems to have gone up. Suspecting fuel in oil. UPDATE: i'm not sure if this is true, it may have been the method of measurement was at fault. Engine hot vs engine cool, perhaps oil just settled quicker in the hot engine.

- Decided to try to drive 7 miles back to lake instead of 30 miles to my home.

- On the way back to the lake, I saw oil splatter on the passenger side window. (Rust preventive feature?)

- Even with all this smoke pouring out I didn't notice any loss of power, but was driving gently to avoid causing more issues.

- Deuce is now parked at Lake.

My initial question are:

- Which TM has the procedure for this type of repair?

- What are the possible issues?

- I would like to do a compression check. Any particular compression tester recommended?

- Other advice?

A few more facts:

- Less than 100 miles on the oil, oil filters and fuel filters.

- Coolant level OK

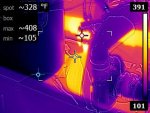

- I happened to have a FLIR Thermal Imaging camera with and took the following measurements just after I returned to the lake These are max readings while Deuce was still idling before shutdown:

- Tip of exhaust pipe: 223 F

- Radiator: 166 F

- Exhaust portion of exhaust manifold area: 408F

- Valve cover: 182 F

- Engine a few inches below injector: 181 F

Last edited: