ida34

Well-known member

- 4,117

- 29

- 48

- Location

- Dexter, MI

RE: Re: RE: Accessory drive seal leaking bad on cummins engi

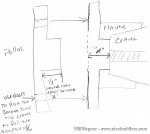

I forgot. Thanks for the pics. It really helps to know exactly what I am looking at. Line drawings can be deceptive. I used to be a certified mechanic but have never worked on a lot of diesel engines.

I forgot. Thanks for the pics. It really helps to know exactly what I am looking at. Line drawings can be deceptive. I used to be a certified mechanic but have never worked on a lot of diesel engines.