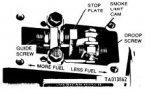

This is the one I have...pic from TM 9-2910-226-34, page 3-105:

Pics of my actual pump are on page 1 of this thread (sorry for jacking it maddawg308! But its in keeping with your pump thread)

Tell me something...I know all pumps are different, and I just want to eliminate the simple before going too deep. I know the filters were replaced not all that long ago, maybe 1500 miles. The truck has been exactly like this the whole time I owned it, which is aprox. 1300 miles. Part of me wants to swap out the filters anyway, but I don't see where it can be a filter issue. I'm obviously getting fuel, as there is smoke. And the boost is low, pointing to a pump or turbo issue.

Jim

Pics of my actual pump are on page 1 of this thread (sorry for jacking it maddawg308! But its in keeping with your pump thread)

Tell me something...I know all pumps are different, and I just want to eliminate the simple before going too deep. I know the filters were replaced not all that long ago, maybe 1500 miles. The truck has been exactly like this the whole time I owned it, which is aprox. 1300 miles. Part of me wants to swap out the filters anyway, but I don't see where it can be a filter issue. I'm obviously getting fuel, as there is smoke. And the boost is low, pointing to a pump or turbo issue.

Jim

Last edited:

Have you not heard of the "50 cent trick"? When I was in the Army and had a Deuce as my daily driver, us mechanics used to give them the 50 cent trick. It is very simple to do and you dont have to risk turning some screw. We called it 50 cent because we used two quarters. Now, we got cheep and started using washers that were the thickness of the quarters. Simply remove the little round cover with the three bolts on the top of the injector pump, pull out the spring, drop in the quarters/washers, replace the spring, tighten the bolts and VOILA!!! You have more power and more smoke. You can take out one washer if you like for less power. Makes a huge difference. And for SURE have a pyrometer to monitor the temp. My C turbo screams like a jet engine!!

Have you not heard of the "50 cent trick"? When I was in the Army and had a Deuce as my daily driver, us mechanics used to give them the 50 cent trick. It is very simple to do and you dont have to risk turning some screw. We called it 50 cent because we used two quarters. Now, we got cheep and started using washers that were the thickness of the quarters. Simply remove the little round cover with the three bolts on the top of the injector pump, pull out the spring, drop in the quarters/washers, replace the spring, tighten the bolts and VOILA!!! You have more power and more smoke. You can take out one washer if you like for less power. Makes a huge difference. And for SURE have a pyrometer to monitor the temp. My C turbo screams like a jet engine!!