JasonS

Well-known member

- 1,643

- 126

- 63

- Location

- Eastern SD

I have one at work because I need to dry desiccant. Look on the used market for deals.Sounds expensive. How much does a vacuum oven cost ? and why do you have one ?

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

I have one at work because I need to dry desiccant. Look on the used market for deals.Sounds expensive. How much does a vacuum oven cost ? and why do you have one ?

Basically it is a time factor. whether you drive the truck or not, the desiccant absorbs moisture from the air. Usually a unit like the Haldex or Bendix will last 3 years before needing replacing. That is why our busses are on a yearly schedule and not a mileage schedule for change-out.So the worst thing for them is what? Sitting for extended periods? I'm already nipple deep in it with the Haldex, so I'll be running it and see how it goes.

Do they offer a 24v version? Their site didn't really say one way or another.Try this place. http://truckpartsetc.com/sales/

Today I called the place rustystud linked. I asked if their AD9 air dryer was available in 24V or was only 12V. The fellow offered to check and call me back. About 30 minutes later he did and a 24v version was available from his supplier in Chicago for ~$235, new, plus UPS S&H which he estimated at about $20. I asked and he did say that he believes it does come with the wire harness and mounting bracket.Is that with mounting brackets and wiring harness? The site I posted has the bare unit for 200. I ask because they don't specify much detail on the site you posted. I suppose I could call but at the moment I'm dealing with more pressing issues than an air dryer. (Dead alternater for one)

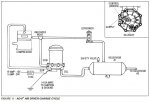

Thank you. I'm not sure why Evco made me the red hose as I had said it was a vehicle application. I'll need to talk to a more experience employee next time. On the bright side, hey, least I'll get it made shorterView attachment 573411Valence, there is one thing I would change. That is to replace that red hose with DOT nylon air-hose. Here's a picture of how mine is installed.

I'm going to say "Yes". (Did someone like me just answer a question from Gimpy? Whoa.)So is the general consensus that the cross-member behind the air tanks is the best location?

You can take additional pictures the next time you're under there, but I believe I understand you just fine otherwise. Thank you.I used a 10 gauge plate and mounted my air-dryer to that. Then mounted the whole thing to the cross member. I thought I had some pictures, but I cant' seem to find them. If you want I can take some better pictures of my mounting system.

I thought the heater was to dry out the descant, and the control port (via the governor) controlled when the air dryer ran.Remember the electrical power needs to go to some kind of thermal switch/relay. You don't want power to the heater in warm weather, only when it gets down to freezing.

We get it, advertisements are annoying!

Sure, ad-blocking software does a great job at blocking ads, but it also blocks useful features of our website like our supporting vendors. Their ads help keep Steel Soldiers going. Please consider disabling your ad blockers for the site. Thanks!