ZDDP SAE paper 7700876 02011977.docx which I can't afford

Paper #:

· 770087

Published:

· 1977-02-01

DOI:

· 10.4271/770087

Citation:

Pless, L. and Rodgers, J., "Cam and Lifter Wear as Affected by Engine Oil ZDP Concentration and Type," SAE Technical Paper 770087, 1977, doi:10.4271/770087.

Author(s):

·

Loren G. Pless

·

John J. Rodgers

Affiliated:

·

Fuels and Lubricants Dept., General Motors Corp.

Pages:

14

Abstract:

The recent increase in excessive camshaft and lifter wear after extended service has shown that some SE-quality engine oils do not provide adequate protection.

To determine the effects of oil additives on wear, controlled tests were run using 1972-1974 model cars, unleaded gasoline, and either SE commercial products or experimental formulations. Field experience with 1970-1975 model trucks, leaded gasoline, and SE/CC or SE/CD oils was also investigated.

With some commercial oils, in both controlled tests and field experience, excessive wear sometimes occurred after extended service, even with recommended oil-change intervals.

Generally, protection from excessive wear was best provided by those oils containing pre-dominantly alkyl ZDP (zinc dithiophosphate) antiwear additive instead of aryl ZDP. These results show that a laboratory engine test is needed to evaluate the long-term wear protection of engine oils.

Anyhow if I just put Rottella T in the multifuel, {five gallons!}, filter it good and change it often is that good enough or am I wasting time and money?

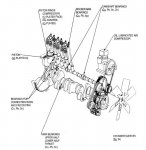

View attachment 584762

and this from 2008

View attachment 584763