Mohawk Dave

Member

- 226

- 14

- 18

- Location

- CA

Hey guys,

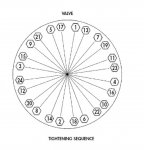

I have the 24 bolt HMMWV rims, the ones with paired bolts (the heavy duty of the 2 24 bolt versions) and can not find the torque specs any where on SS or the web. Tried TWF and everywhere else. I found the specs for 12 bolt, but not mine.

I also know that you re-torque periodically, after something like 50 miles, then 500 miles, then every 3k from then on.....or similar, but you catch my drift. Is any one certain of the specs?

Thanks in advance.

Dave

I have the 24 bolt HMMWV rims, the ones with paired bolts (the heavy duty of the 2 24 bolt versions) and can not find the torque specs any where on SS or the web. Tried TWF and everywhere else. I found the specs for 12 bolt, but not mine.

I also know that you re-torque periodically, after something like 50 miles, then 500 miles, then every 3k from then on.....or similar, but you catch my drift. Is any one certain of the specs?

Thanks in advance.

Dave