- 1,181

- 2,064

- 113

- Location

- Wenatchee, WA

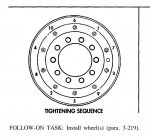

I've been looking for the torque spec for the nuts that fasten the two halves of the A2 combat wheels with the 3/4" studs, but I haven't found anything. Does anyone know what the correct range is? Does it differ by brand of wheel?