Along with the leaking air when on the brakes the primary tank would slowly leak down after turning the engine off to zero where the secondary was still holding pressure. Replaced one of the front brake canisters with a new one and now the pressure holds in the primary tank. Still have a leak through the stack when on the brakes, but it is much slower now. This was only replacing one canister and still have others to replace along with on known bad large spring brake unit. Also gonna replace the Q2 valve in the front near the engine as it was only $20.

Hope to know more tomorrow after the seals are replaced on the none spring brake canisters and the value replaced. The spring brake part will not be in until Monday, but hoping it will all be good without having to replace any of those.

Just wanted to update this post, looking like my mechanic is getting closer to a solution on these brakes. Last is a small fuel leak that should be easy fix. I could do these myself, but the guy buying the truck from me wants my mechanic to do the work.

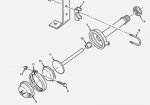

This is from one of the small canisters, looks like that pinch may have been a leak.

This is from the shaft to the spring brake (not the larger 16 in the spring brake).