OK so I had this issue, range selector being hard at shifting from and to low and high, also I had gear oil squirting from dash air switch for front axle engagement.

First I found out all 3 t-case breather vent lines were plugged intentionally with small rubber pieces, per advice from forum members guidance I was able to remove the plugs and fix it. No one has ever told me as of yet why would someone do that. (I don't know if it has a good purpose)

After unplugging the breather valves I had hard shifting continued and other day it squirted gear oil again after a death wobble, and this time I said I want to get to bottom of this.

So I did remove both air cylinders.

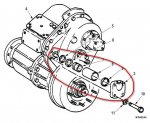

Round sleeves were bit rusty and I also discovered one on the left is Transfer Case Interlock Air Cylinder has a shorter sleeve than the Transfer Case Front Axle Engagement Air Cylinder on the right, also metal of the plunger was bit different in color and metal but same in shape and size.

Here comes the shocking part.

There was no push rod lock

Parts manual Vol1 on page 0217-3 says the part number is 2244-D-30

Now there are 2 mysteries going on here and I hope someone can help me...

1-Where did the rod go? I can assume 2 things, one is rod fell through inside the t-case balancing on it's tip before falling between one of the gears and waiting for the day it will destroy entire transfer case, or Private Smart Cookie E-bay'd it for petty cash, which I prefer over steel rod bouncing around in my t-case. Now I lean towards smart cookie because there was a big spring came out of the Transfer Case Interlock Air Cylinder on top of the plunger instead of bottom (read below).

2-Why is the transfer case is hard to shift if push rod lock is missing? According to operation theory there is a constant air pressure at Transfer Case Interlock Air Cylinder which is pushing the the plunger down to keep it locked which is ON TOP of the spring which is pushing it up trying to unlock it so that when you drain all the air out of the truck you can easily shift but if truck is aired then you have to press the button then the transfer case shift lever which actuates the air solenoid which cuts off incoming air and dumps the air inside the air cylinder so the spring can push up the plunger to unlock the straight shaft.

Questions...

1-So if some one knows or have handled the rod before please tell me if it would be able to fall through, do I need to drop the pan?

2-If I find and replace the rod, do I need to brake into the transfer case or do I just insert it from the top?

3-How is the push lock rod is connected to plunger that when the spring push the plunger up the lock rod is also pulled up with the plunger.

4-If the push lock rod is not there, why is it still difficult to shift when the truck is aired?

5-How to I go about getting the lock shaft and where?

6-Is the oil coming up from Case Front Axle Engagement Air Cylinder Switch on the dash because of the constant air supply into the transfer case built up because of defective/incomplete Transfer Case Interlock Air Cylinder?

Thank you for reading, and I would appreciate if you respond...

As of answers from other forum members, careful inspection of the transfer case and looking at diagrams for two days while verifying air hose connections, I came up with a pretty good understanding of how the system actually works which when I explain it below in hopes of someone else will be able to troubleshoot their own system properly.

Main Problem

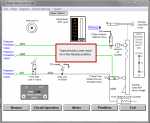

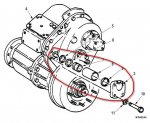

The red circle shows the transfer case breather which has 3 connections on top, even though this did not make any sense for me at first, a local MV collector explained that for deep water fording purposes it has enclosed system.

GREEN Circle is the line little thicker than other two is the line coming from the handbrake in the cab, so when driver pulls the handbrake this is where the air is vented, which I believe (correct me if I am wrong) releases the air in rear brake lines which basically anchors the truck in place.

BLUE Circle is the line that exhaust air from the air solenoid (you can see the line in the pic) which releases the lock rod in the transfer case when you press the button on the Hi n Lo selector in the cab before changing it.

ORANGE Circle is the actual line that goes to air intake as a main exhaust, so in case if that line is clogged means every time you release handbrake or press the button on range selector on the floor for transfer case, all of that air is pressurized in the t-case.

My Findings

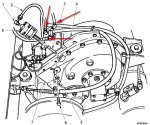

I have removed the entire breather T adapter for inspection and cleaning, but you must remove the Air Solenoid and bracket for it before you can fully unscrew the breather adapter which I was not able to do before because with the spare tire carrier it is very difficult to reach, since I removed the entire assembly I can not tell if there was a little plate you can unbolt and get this assembly but it is all worth it if your Front Axle Engagement Switch is dripping GEAR oil, not engine oil.

As you can see in the picture I had the ORANGE Line connection was completely blocked with little rubber pieces, there actually were more than that, but when I blew air in it, those were the ones I could catch. Surprisingly I have unclogged this line from more rubber pieces month before but I didn't know there was another battalion of them waiting in line inside the adapter ready for me to hook the line up and keep clogging the line. This was the main reason why the t-case was pressurized which caused gear oil being pumped into the cab from t-case, but not the only reason.

Theory of Operation

Now I figured there was the second problem, which also explain why Private Smart Cookie blocked all the vent lines.

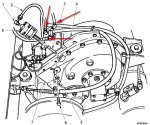

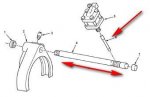

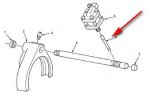

TURQUOISE Circle is actually is the air supply line which keeps a constant air supply to the Air Solenoid then directed to PURPLE circle without a disruption so the push lock rod (red arrow) inside the air cylinder stays pushed in keeping the range selector kicking back out of gear in case of heavy load I assume. And when the button on the range selector in the cab is pressed it cuts the air supply from the air cylinder and dump the air inside air cylinder from vent line to breather T adapter which then a spring under the plunger piston moves up freeing slots on the main shaft inside t-case is unlocked for driver to change the gears.

Problem arises from the air cylinder plunger piston's rubber flapper seals are worn out!!!

Because of there is constant air supply at the piston so it can keep the push lock rod down keeping the shaft locked in, if the seal is bad it leaks the air into the t-case out the breather at a substantial rate, which causes another problem, truck takes forever to air up to be able to drive.

So the Pv. Cookie who somehow could not change the seals to keep a good air pressure build up in the truck thought if I block the all the ports on the t-case breather I can get the truck build up enough air fast enough the pass the inspection since no one ever drive the truck anyways.

Chain of Problems

But when the Pv. Cookie blocked the vent ports caused few other problems, now because of the air solenoid vent port is blocked he had to remove the push lock rod from the t-case because air solenoid could not vent air from the air cylinder causing push lock rod staying locked and Hi n Lo range selector can't be changed.

Pv. Cookie also didn't know that the air solenoid that actuates the front axle is also have the same setup with a plunger piston and flapper seal connected to lower back of the same t-case is low enough to pick up gear oil circulating and pump it to dash switch because it has a bad flap seal too.

Also it was very inconsiderate of him that by blocking the air vented from the handbrake he was risking other people's lives by not exhausting brake lines properly risking damage to surrounding.

Identical pistons

The way the Front Axle Engagement Switch works is it basically an air loop with a switch, unlike the push lock rod it doesn't keep constant pressure at the plunger piston instead when switched on it supplies air to plunger piston until driver turns it off which then pressurized air runs back at the switch and vents at the switch there into the cab, that's where the gear oil comes from.

In my book if you cheat you lose just as if you snooze, Pv. Cookie might have pass his unit with excellent maintenance record but if that switch start dripping oil middle of critical mission, t-case busted under heavy load because it had very little or no oil, or handbrake lost grip on a slope and crushed something or someone would more spell out a disaster. But I still got kudos for him some how he was smart enough to be able to figure out a very complex but easy solution for a very simple problem.

I hope he continues his life using his gift for good for all.

And I hope this helps someone down the road.

Thank you for reading,

And please don't forget to change you transfer case air cylinder plunger piston flapper seals.

I think simp5782 have those.

First I found out all 3 t-case breather vent lines were plugged intentionally with small rubber pieces, per advice from forum members guidance I was able to remove the plugs and fix it. No one has ever told me as of yet why would someone do that. (I don't know if it has a good purpose)

After unplugging the breather valves I had hard shifting continued and other day it squirted gear oil again after a death wobble, and this time I said I want to get to bottom of this.

So I did remove both air cylinders.

Round sleeves were bit rusty and I also discovered one on the left is Transfer Case Interlock Air Cylinder has a shorter sleeve than the Transfer Case Front Axle Engagement Air Cylinder on the right, also metal of the plunger was bit different in color and metal but same in shape and size.

Here comes the shocking part.

There was no push rod lock

Parts manual Vol1 on page 0217-3 says the part number is 2244-D-30

Now there are 2 mysteries going on here and I hope someone can help me...

1-Where did the rod go? I can assume 2 things, one is rod fell through inside the t-case balancing on it's tip before falling between one of the gears and waiting for the day it will destroy entire transfer case, or Private Smart Cookie E-bay'd it for petty cash, which I prefer over steel rod bouncing around in my t-case. Now I lean towards smart cookie because there was a big spring came out of the Transfer Case Interlock Air Cylinder on top of the plunger instead of bottom (read below).

2-Why is the transfer case is hard to shift if push rod lock is missing? According to operation theory there is a constant air pressure at Transfer Case Interlock Air Cylinder which is pushing the the plunger down to keep it locked which is ON TOP of the spring which is pushing it up trying to unlock it so that when you drain all the air out of the truck you can easily shift but if truck is aired then you have to press the button then the transfer case shift lever which actuates the air solenoid which cuts off incoming air and dumps the air inside the air cylinder so the spring can push up the plunger to unlock the straight shaft.

Questions...

1-So if some one knows or have handled the rod before please tell me if it would be able to fall through, do I need to drop the pan?

2-If I find and replace the rod, do I need to brake into the transfer case or do I just insert it from the top?

3-How is the push lock rod is connected to plunger that when the spring push the plunger up the lock rod is also pulled up with the plunger.

4-If the push lock rod is not there, why is it still difficult to shift when the truck is aired?

5-How to I go about getting the lock shaft and where?

6-Is the oil coming up from Case Front Axle Engagement Air Cylinder Switch on the dash because of the constant air supply into the transfer case built up because of defective/incomplete Transfer Case Interlock Air Cylinder?

Thank you for reading, and I would appreciate if you respond...

UPDATE 07/14/2016

As of answers from other forum members, careful inspection of the transfer case and looking at diagrams for two days while verifying air hose connections, I came up with a pretty good understanding of how the system actually works which when I explain it below in hopes of someone else will be able to troubleshoot their own system properly.

Main Problem

The red circle shows the transfer case breather which has 3 connections on top, even though this did not make any sense for me at first, a local MV collector explained that for deep water fording purposes it has enclosed system.

GREEN Circle is the line little thicker than other two is the line coming from the handbrake in the cab, so when driver pulls the handbrake this is where the air is vented, which I believe (correct me if I am wrong) releases the air in rear brake lines which basically anchors the truck in place.

BLUE Circle is the line that exhaust air from the air solenoid (you can see the line in the pic) which releases the lock rod in the transfer case when you press the button on the Hi n Lo selector in the cab before changing it.

ORANGE Circle is the actual line that goes to air intake as a main exhaust, so in case if that line is clogged means every time you release handbrake or press the button on range selector on the floor for transfer case, all of that air is pressurized in the t-case.

My Findings

I have removed the entire breather T adapter for inspection and cleaning, but you must remove the Air Solenoid and bracket for it before you can fully unscrew the breather adapter which I was not able to do before because with the spare tire carrier it is very difficult to reach, since I removed the entire assembly I can not tell if there was a little plate you can unbolt and get this assembly but it is all worth it if your Front Axle Engagement Switch is dripping GEAR oil, not engine oil.

As you can see in the picture I had the ORANGE Line connection was completely blocked with little rubber pieces, there actually were more than that, but when I blew air in it, those were the ones I could catch. Surprisingly I have unclogged this line from more rubber pieces month before but I didn't know there was another battalion of them waiting in line inside the adapter ready for me to hook the line up and keep clogging the line. This was the main reason why the t-case was pressurized which caused gear oil being pumped into the cab from t-case, but not the only reason.

Theory of Operation

Now I figured there was the second problem, which also explain why Private Smart Cookie blocked all the vent lines.

TURQUOISE Circle is actually is the air supply line which keeps a constant air supply to the Air Solenoid then directed to PURPLE circle without a disruption so the push lock rod (red arrow) inside the air cylinder stays pushed in keeping the range selector kicking back out of gear in case of heavy load I assume. And when the button on the range selector in the cab is pressed it cuts the air supply from the air cylinder and dump the air inside air cylinder from vent line to breather T adapter which then a spring under the plunger piston moves up freeing slots on the main shaft inside t-case is unlocked for driver to change the gears.

Problem arises from the air cylinder plunger piston's rubber flapper seals are worn out!!!

Because of there is constant air supply at the piston so it can keep the push lock rod down keeping the shaft locked in, if the seal is bad it leaks the air into the t-case out the breather at a substantial rate, which causes another problem, truck takes forever to air up to be able to drive.

So the Pv. Cookie who somehow could not change the seals to keep a good air pressure build up in the truck thought if I block the all the ports on the t-case breather I can get the truck build up enough air fast enough the pass the inspection since no one ever drive the truck anyways.

Chain of Problems

But when the Pv. Cookie blocked the vent ports caused few other problems, now because of the air solenoid vent port is blocked he had to remove the push lock rod from the t-case because air solenoid could not vent air from the air cylinder causing push lock rod staying locked and Hi n Lo range selector can't be changed.

Pv. Cookie also didn't know that the air solenoid that actuates the front axle is also have the same setup with a plunger piston and flapper seal connected to lower back of the same t-case is low enough to pick up gear oil circulating and pump it to dash switch because it has a bad flap seal too.

Also it was very inconsiderate of him that by blocking the air vented from the handbrake he was risking other people's lives by not exhausting brake lines properly risking damage to surrounding.

Identical pistons

The way the Front Axle Engagement Switch works is it basically an air loop with a switch, unlike the push lock rod it doesn't keep constant pressure at the plunger piston instead when switched on it supplies air to plunger piston until driver turns it off which then pressurized air runs back at the switch and vents at the switch there into the cab, that's where the gear oil comes from.

In my book if you cheat you lose just as if you snooze, Pv. Cookie might have pass his unit with excellent maintenance record but if that switch start dripping oil middle of critical mission, t-case busted under heavy load because it had very little or no oil, or handbrake lost grip on a slope and crushed something or someone would more spell out a disaster. But I still got kudos for him some how he was smart enough to be able to figure out a very complex but easy solution for a very simple problem.

I hope he continues his life using his gift for good for all.

And I hope this helps someone down the road.

Thank you for reading,

And please don't forget to change you transfer case air cylinder plunger piston flapper seals.

I think simp5782 have those.

Last edited: