- 634

- 13

- 18

- Location

- Cordova, Alaska

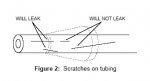

Here goes, 2 of my injector lines are leaking. Its between the nut and the hydro head (pic attached). I assume there is an o-ring or seal of some sort in there but I cant find anything in the tm9-2910-226-34. Thanks for the help.

Attachments

-

47.7 KB Views: 62