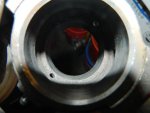

Here's what I've learned so far: There are 3 point that need to be greased having to do with the clutch. One on each end of the clutch control rod (traverses sideways across bell housing and operates the throw out bearing) and one on the back of the throw out bearing (to allow it to slide fore and aft along the input shaft to the tranny), but not the actual bearing itself. It appears that a common misconception is that "lubing the throw out bearing" means pushing grease into the throwout bearing holder, which slides fore and aft. That grease doesn't actually flow to the throwout bearing itself. I've also heard that people hand pack the throwout bearing, but if that's the case, then that grease would spin out quickly and leave it dry, again. I talked to a wrench at Memphis Equipment today and he said that the throwout bearings are pre-lubed, sealed units that don't ever need lube. That makes sense, but I have two bearings here that have no permanent seals. Could it be that they degraded over the decades and just aren't there anymore? Maybe the newer throwout bearings are now sealed instead of open, as may have been in the past? Anyone have the number on a sealed throwout bearing that can be had at a local auto parts store?

Jim