- 34,014

- 1,814

- 113

- Location

- GA Mountains

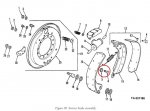

In light of my recent brake failure and findings I wanted to post this as a sticky. Folks, do regular brake inspections on your deuce. Check that brake fluid as much as you do the oil, could save a life. WARNING, for all you guys with older deuces I've found a potential problem. My 1953 Stude has a unique and apparently failure prone hold down design. The newer trucks had a shouldered bolt of sorts used as a hold down. Its bolted through the backing plate to insure your shoes stay put. The ones on my truck utilize a stud affixed to the backing plate which has a flat washer on the shoe and is held in place by a cotter pin. Mine blew apart and tore up some stuff with it. I'll be removing the studs and replacing them with the shouldered bolts. The TM 9-8022 also makes reference to a 3rd design using the bendable horse shoe washers. Better that cotter pins, not as good as bolts. I encourage every deuce owner to do a brake check. Add it to a regular service or at least yearly as Ryan said. Be careful!

See this thread for Airpack rebuild and warnings

http://www.steelsoldiers.com/index.php?name=PNphpBB2&file=viewtopic&t=8063

See this thread for Airpack rebuild and warnings

http://www.steelsoldiers.com/index.php?name=PNphpBB2&file=viewtopic&t=8063