- 387

- 908

- 93

- Location

- Mesa, Colorado

'04 A1. I also had a few over voltage codes on the trans. It All began when the starter shorted. I still have to take the pulled Neihoff to the repair shop.Found all of your 28SI alternator posts here:

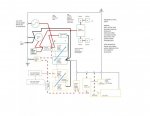

Alternate Alternator Selection

Just another data point, my 2 6tl flooded (770ca) didn't have enough juice to start my C7 at about -10F. Supposedly agm are better cca at over 1000 for most brands. I may end up with 4x agm 6tl to deal with WI winter. Yes the AGM's are 1150 CCA each. And they aren't nearly as affected by cold...www.steelsoldiers.com

Pretty much the exact setup I was searching for. I will be knocking that off completely if/when my 100A Neehoff dies. Hoping to extend its life a bit by running a 24v setup only, but I am getting some voltage spikes on the trans currently as I mentioned in first post...

I tried searching your posts but didn't see any reference, what year/make is your truck ? A1 or A1R ?

if you do this swap double check the existing belt length before ordering a shorter one. I used the wrong length at first. So my initial replacement was barely able to fit.

Last edited: