I ran into the drivers door would ovationally bounce open when closing . No adjustment would help . Finally my dumb ass pulled the panel back off and lubed the inside of the latch that was sticking . Works like butter now .It seems like it is a common mod that they did in the field to cut the pins off and hinge the doors on the stubs. I bought replacement pins, I think from E.I. It was a trick to get the remains of the old pins out, but nothing a torch , 6 lb sledge, an a lot of determination couldn't deal with. I haven't had any issues with the E.I. pins, but do try to remember to oil them regularly.

I have I think an unrelated (maybe) issue with my passenger door. It will not stay latched. Now that I think of it, this issue started right after I replaced the hinge pins. Full disclosure I have not gotten serious about fixing it, but I have tried to adjust the latch a couple of times. The little half moon latch just does not go past the tipping point to hold it shut. Right now I am holding it shut with a couple of zip ties. I also somehow lost the driver side door handle. Kind of a pain, but other issues are higher on my list.

-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

FLU419 SEE HMMH HME Owners group

- Thread starter Migginsbros

- Start date

More options

Who Replied?rtrask

Well-known member

- 342

- 251

- 63

- Location

- San Luis Valley, Colorado

I bought a good quality laser level, and it saved my bacon. The Harbor Freight laser level was a impossible to get right, and it was not even close. I have a gravity flow septic system and the depth is critical to get right. I was digging in the wrong place. I had to move it out another 120 feet.You may be overthinking this, Ron.

When the SEE is higher in relation to the bottom of the "floor" you obviously need to dig a bit deeper, and vice versa. Since you'll have to stop digging and reposition every 12 feet or so anyway, that's a good time to use a laser, mirror (if the sun is out), transit, or flashlight (if it's dark) to keep track of how level the trench is.

I bet you'll get the hang of it after the first 20 feet or so.

I also bought a book, "Operating Techniques for the Tractor Loader Backhoe" by Gary J. Ober. I have found it very helpful. The chapter on Machine Control has different exercises for beginning operators. Try this some time, it is called float the bucket. Extend the backhoe all the way out with the bucket fully open and the teeth about 2 " off the ground. Pull the the dipper, and boom back and maintain the 2" following the contour of the ground. I have not been able to do it, but trying to do it has given me the idea I was looking for to dig a trench with a smooth bottom. I still need to work on getting the depth just right, but I think it is just practice, and more frequent checking.

- 3,338

- 1,319

- 113

- Location

- The actual midwest, NM.

Oddly enough, I find it much easier to dig a trench/ditch with a SEE and its many levers than with a modern 2-stick.

That's likely because of more practice.

Anyway, since what I'm digging doesn't usually have to be all the precise (within two inches of level is plenty over short distances) I tend to use the dipper or bucket as a depth gauge, relative to the ground.

In my case it's just irrigation ditches, but the principle must be the same, to keep the flow at the correct speed.

Why I insist on making horse graves perfectly rectangular and try making the bottom level (some nine feet down) I'll never understand.

That's likely because of more practice.

Anyway, since what I'm digging doesn't usually have to be all the precise (within two inches of level is plenty over short distances) I tend to use the dipper or bucket as a depth gauge, relative to the ground.

In my case it's just irrigation ditches, but the principle must be the same, to keep the flow at the correct speed.

Why I insist on making horse graves perfectly rectangular and try making the bottom level (some nine feet down) I'll never understand.

rtrask

Well-known member

- 342

- 251

- 63

- Location

- San Luis Valley, Colorado

For the last couple of years I have fought that door. I didn't even get it out of the door I used electronic contacts cleaner and sprayed it through the door handle hole and bolted it back in. and it worked the first time I tried.I ran into the drivers door would ovationally bounce open when closing . No adjustment would help . Finally my dumb ass pulled the panel back off and lubed the inside of the latch that was sticking . Works like butter now .

rtrask

Well-known member

- 342

- 251

- 63

- Location

- San Luis Valley, Colorado

I have had a few internal conversations with myself if I should post on this or not, but decided I might as well. For the last couple of weekends I have been working on the leach field for our septic system. The leach field needs to be 12 feet wide and 76 feet long. I dug 2 trenches 14 feet apart outside edge to outside edge.

I thought originally I would be able to just make a third pass through will the SEE on the ground between the trenches. It was too narrow for that, so I dug out between, then when I had enough space I dropped the SEE into the bed of the leach field, and dug out the dirt between the original 2 trenches. At least that was the theory.

It was hard to clean the spoil out; it was also weird digging above the level of the stabilizers. As I went, I thought after I got what I could with the backhoe I could use the front end loader to remove the spoil the backhoe left behind. That turned out to be not as easy as the thought made it seem.

I have been using the front end loader and I retract some of my disparaging remarks on the front end loader. My initial issue was a slipping belt on the front hydraulic pump. I am still learning how to work it, but after I tightened the belt, it is pretty functional on loose material. I have learned to get a full bucket and it will be a lot more effective at grading the bed once I have removed the bulk of the material, but loose or not it seems really slow to make progress using the front end loader with all the driving around to fill and dump it out. The laser level says I need to remove about 18" on the high side. I intend to work from low to high, thinking that pulling the bucket into the deeper material will allow me to get the spoil into the bucket. The problem before from the pictures above was there was nothing to act as backing when I pulled the soil down.

If anyone has any suggestions on a better approach, or if you think I should stick with the front end loader, I am all ears.

I thought originally I would be able to just make a third pass through will the SEE on the ground between the trenches. It was too narrow for that, so I dug out between, then when I had enough space I dropped the SEE into the bed of the leach field, and dug out the dirt between the original 2 trenches. At least that was the theory.

It was hard to clean the spoil out; it was also weird digging above the level of the stabilizers. As I went, I thought after I got what I could with the backhoe I could use the front end loader to remove the spoil the backhoe left behind. That turned out to be not as easy as the thought made it seem.

I have been using the front end loader and I retract some of my disparaging remarks on the front end loader. My initial issue was a slipping belt on the front hydraulic pump. I am still learning how to work it, but after I tightened the belt, it is pretty functional on loose material. I have learned to get a full bucket and it will be a lot more effective at grading the bed once I have removed the bulk of the material, but loose or not it seems really slow to make progress using the front end loader with all the driving around to fill and dump it out. The laser level says I need to remove about 18" on the high side. I intend to work from low to high, thinking that pulling the bucket into the deeper material will allow me to get the spoil into the bucket. The problem before from the pictures above was there was nothing to act as backing when I pulled the soil down.

If anyone has any suggestions on a better approach, or if you think I should stick with the front end loader, I am all ears.

- 3,338

- 1,319

- 113

- Location

- The actual midwest, NM.

The SEE's loader and I don't get along very well, largely due to a lack of practice, but also the somewhat awkward 2-lever setup, and primarily because of the suspension.

Anyway, what I'd do with your trench (using the tractor's loader instead since I can operate that one much better and faster) would be to back the tractor in, followed by my 16-foot dump trailer. That would eliminate taking the dirt out one bucket load at a time.

Once the bottom was in decent shape I'd go in with my "Frankenblade" (a towable grader of sorts) and make it all level and even.

But if all I had was a SEE, I'd get it all somewhat close, then have a good operator with a small dozer come in and do the finish work, and finally use the SEE's loader to get the last dirt out from the end of the trench.

Anyway, what I'd do with your trench (using the tractor's loader instead since I can operate that one much better and faster) would be to back the tractor in, followed by my 16-foot dump trailer. That would eliminate taking the dirt out one bucket load at a time.

Once the bottom was in decent shape I'd go in with my "Frankenblade" (a towable grader of sorts) and make it all level and even.

But if all I had was a SEE, I'd get it all somewhat close, then have a good operator with a small dozer come in and do the finish work, and finally use the SEE's loader to get the last dirt out from the end of the trench.

glcaines

Well-known member

- 3,904

- 2,571

- 113

- Location

- Hiawassee, Georgia

I can do fairly accurate work with the backhoe on my FLU419, especially digging ditches, and the more I use it the better I get. However, almost every time I try to do accurate work with the loader, I end up parking and switching to my John Deere 5520 tractor and loader, which is much easier to do accurate work with because of the joystick. I agree with The FLU farm, the two levers for the loader on the FLU419 are difficult to manipulate and control the bucket. It would have been much better to have a joystick instead of the two levers. I've been using the loader on the FLU today to pick up bucket loads of material and driving down the highway several miles to dump where the material is needed. This is actually one case where the FLU419 is better than my JD 5520 loader.

- 3,338

- 1,319

- 113

- Location

- The actual midwest, NM.

Dang. And here I use a dump trailer to move dirt even just 100 feet, instead of using the loader for multiple trips.I've been using the loader on the FLU today to pick up bucket loads of material and driving down the highway several miles to dump where the material is needed. This is actually one case where the FLU419 is better than my JD 5520 loader.

dcheat

New member

- 1

- 3

- 3

- Location

- Ravensdale, WA

Heya fellas. After a good deal of reading I cant seem to find an answer to this. I need help. How slow is 1st gear low range?

Low range on my FLU seems to be remarkably fast. To the point that it makes front end loader work a difficult. Engine wants to stall with every push into the material. And I feel like im going to roll the damn thing just due to how I cant keep her in a nice low speed. I Really don't want to toast my clutch but im off and on that thing way to frequently to keep her at a low enough speed to not be very wibbly woobly. Perhaps im just too used to an actual tractor. But ive driven other mogs with a Much lower 1st gear.

Is my FLU not properly going into low range?

Or is the FLU loader only good for super loose material?

Low range on my FLU seems to be remarkably fast. To the point that it makes front end loader work a difficult. Engine wants to stall with every push into the material. And I feel like im going to roll the damn thing just due to how I cant keep her in a nice low speed. I Really don't want to toast my clutch but im off and on that thing way to frequently to keep her at a low enough speed to not be very wibbly woobly. Perhaps im just too used to an actual tractor. But ive driven other mogs with a Much lower 1st gear.

Is my FLU not properly going into low range?

Or is the FLU loader only good for super loose material?

- 3,338

- 1,319

- 113

- Location

- The actual midwest, NM.

I don't remember the ratio/minimum speed, but a SEE is too fast in 1st for my liking, both for loader work and my snow blower.

Like you, I also think that loader work can be hard on the clutch. And the loader is indeed intended for loose materials.

It would be great to have crawler gears like in an MB4-94 (2000:1), or maybe better yet, hydrostatic drive as in a FLU HME.

So, for loader work I use the tractor instead. It's much quicker and far more precise.

Like you, I also think that loader work can be hard on the clutch. And the loader is indeed intended for loose materials.

It would be great to have crawler gears like in an MB4-94 (2000:1), or maybe better yet, hydrostatic drive as in a FLU HME.

So, for loader work I use the tractor instead. It's much quicker and far more precise.

glcaines

Well-known member

- 3,904

- 2,571

- 113

- Location

- Hiawassee, Georgia

I have actually used the loader on my tractor to pick up material and dump it in the loader on the FLU to drive it on the road to where the material was needed. Much faster and more accurate removal of material.I don't remember the ratio/minimum speed, but a SEE is too fast in 1st for my liking, both for loader work and my snow blower.

Like you, I also think that loader work can be hard on the clutch. And the loader is indeed intended for loose materials.

It would be great to have crawler gears like in an MB4-94 (2000:1), or maybe better yet, hydrostatic drive as in a FLU HME.

So, for loader work I use the tractor instead. It's much quicker and far more precise.

glcaines

Well-known member

- 3,904

- 2,571

- 113

- Location

- Hiawassee, Georgia

Not a good day today. I was moving some mulch with the loader on my FLU419 through our yard to put on the blueberry bushes. I was already messing the lawn up with the weight. Unfortunately, I sunk far enough that I needed 4X4. Also unfortunately, my 4X4 no longer functions for some reason. I could only spin one rear wheel. I ended up pulling the FLU backwards by myself with my JD 5520 tractor. I had to pull it about 3 - 4 feet and then get out and turn the wheel on the FLU again. I went through that exercise about 15 times before I got the FLU to level ground and could drive it out. Now I need to find out what is broken and fix it. My FLU has been very reliable up until now.

- 3,338

- 1,319

- 113

- Location

- The actual midwest, NM.

That rescue-yourself-alone stuff can get old. Which is why I put an 18,000 lb. winch on the former parts SEE.

Sure enough, haven't got anything stuck since.

Sure enough, haven't got anything stuck since.

MajorMogger

Member

- 47

- 50

- 18

- Location

- Texas

Speedwoble

Well-known member

- 606

- 301

- 63

- Location

- New Holland, PA

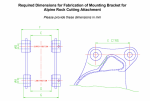

The dimensions would be the same as the 580E.I need some help. I am having a drum cutter mount fabricated for the flu419 so that I can tunnel through solid rock. They need these measurements but I am wondering if there is a known source of accurate measurements for this vs me trying to measure centers etc with my primitive tools.

View attachment 861808

C is 10.12”

B is 1.759-1.762”

D is 5.25”

A is 1.509-1.512”

E is 14.01”

Your definition of dipper and link may be different than mine so use common sense.

Does your cascade shifter still work . That is supplied with air from the unloader clamped to the center beam just behind the trans . This unloader is set at a higher pressure that your air alarm . Mine is set at about 92 psi . . If that works you should have air to the 4wd switch . There is an air cylinder on top of the trans that engages the 4wd by pulling the lever on the rear of the trans farward .Not a good day today. I was moving some mulch with the loader on my FLU419 through our yard to put on the blueberry bushes. I was already messing the lawn up with the weight. Unfortunately, I sunk far enough that I needed 4X4. Also unfortunately, my 4X4 no longer functions for some reason. I could only spin one rear wheel. I ended up pulling the FLU backwards by myself with my JD 5520 tractor. I had to pull it about 3 - 4 feet and then get out and turn the wheel on the FLU again. I went through that exercise about 15 times before I got the FLU to level ground and could drive it out. Now I need to find out what is broken and fix it. My FLU has been very reliable up until now.

View attachment 861569

glcaines

Well-known member

- 3,904

- 2,571

- 113

- Location

- Hiawassee, Georgia

The intermediate speed control works fine. Actually, everything works great except the 4X4. The 4X4 used to work OK and I could hear it when I engaged the switch. Now, there is zero sound when the switch is engaged. My unloader is set at 105 PSI and I don't have any problems maintaining that pressure. I haven't had a chance to work on it yet mostly because of rain and a couple of other projects, but I expect to be able to look at it next week. I suspect an air supply problem either to the switch or from the switch to the cylinder.Does your cascade shifter still work . That is supplied with air from the unloader clamped to the center beam just behind the trans . This unloader is set at a higher pressure that your air alarm . Mine is set at about 92 psi . . If that works you should have air to the 4wd switch . There is an air cylinder on top of the trans that engages the 4wd by pulling the lever on the rear of the trans farward .

- 3,338

- 1,319

- 113

- Location

- The actual midwest, NM.

Check the small rubber hoses at the front wheels first. Easy enough to do, and I've had two go bad.

MajorMogger

Member

- 47

- 50

- 18

- Location

- Texas

Thank you so much! Very helpful. What do you make of the F and G measurements? Why doesn't the diagram go to the outside and what's the meaning of that little circle?The dimensions would be the same as the 580E.

C is 10.12”

B is 1.759-1.762”

D is 5.25”

A is 1.509-1.512”

E is 14.01”

Your definition of dipper and link may be different than mine so use common sense.

Speedwoble

Well-known member

- 606

- 301

- 63

- Location

- New Holland, PA

The F and G dimensions are not specified on my prints, which are for the factory CASE bucket. They would just be C and D plus 2X the thickness of the metal. The FLU backhoe bucket is not made by CASE, so it may be different.Thank you so much! Very helpful. What do you make of the F and G measurements? Why doesn't the diagram go to the outside and what's the meaning of that little circle?

The OEM buckets use a hardened steel bushing in that location.

It looks like that supplier is using a drilled hole to bolt the pins in and the F and G dimensions are the distance from the head of the pin to that hole. I’m not at the FLU to check, but the 224-24P shows C clips on each side of the pins.

- 110,617members

- 165,132threads

- 2,323,446posts

- 1,426online users