treeguy

New member

- 605

- 3

- 0

- Location

- Fort One Bay - Cape Cod, MA

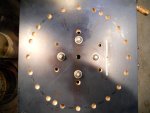

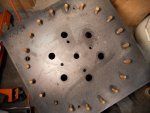

Here are just a couple of the latest pictures I have of my work so far. The first picture is a 1/4" plate (all 3/4" dia. holes). This plate was for working out any possible bugs and a permanent pattern. The second picture is of a 1/2" plate being drilled for holes to clamp it to the milling table. The third pic. is of a stack of three plates with the completed Deuce 6 hole pattern. I have chamfered this top plate and am 3/4 the way through drilling the 20 holes for the studs to press into.

More to follow soon.

More to follow soon.

Attachments

-

77.1 KB Views: 93

-

72.7 KB Views: 107

-

49.5 KB Views: 105