spectre6000

New member

- 96

- 3

- 0

- Location

- Broomfield, CO

Most of my vehicles are much older than my CUCV, and whenever I acquire something new I always replace the wiring harness as a matter of course. Always. I didn't once, and ended up on the side of the road in the Arizona desert in July with the charred remains of a minor engine fire hacking together a replacement for the burned section of harness out of some trailer lighting wire. I've seen so many hacks and electrical fires in my cars and others' that I don't care to repeat those mistakes. Additionally, installing a new harness is WAY easier than trying to track down a grounding wire hiding somewhere deep in the harness or something and you practically eliminate the possibility of future electrical issues for a few decades.

On cars where quality aftermarket harnesses are readily available, I'm more than happy to go the easy route. When that's not the case, it becomes necessary to make a harness. This takes longer, but is a lot of fun (assuming you're into that sort of thing) and gives you the opportunity to modify things a bit.

The electrical system on my M1009 is pretty well trashed. Some things sort of work, but I haven't found much electrical that fully works as expected that I didn't recently replace or rebuild myself. Most everything that isn't steel in my truck has all but turned to chalk, so instead of trying to track down and terminate the gremlins one by one just so they can continue to breed and multiply in the chalky insulated recesses of my truck, I'm going to shotgun the thing and make the electrons happy.

Since the civilian harnesses all include power windows and that sort of thing, I really don't care to go that route. The military replacement harnesses will be 30 years old, stiff, and also have a bunch of junk I don't need (the truck is to be a workhorse, occasional off road rig, and occasional daily driver, so blackout lights are kind of silly). I don't think there are any harnesses available for civilian market trucks without any power accessories, AC, and the like. That means I'm pretty much on my own. This is NOT a bad thing!

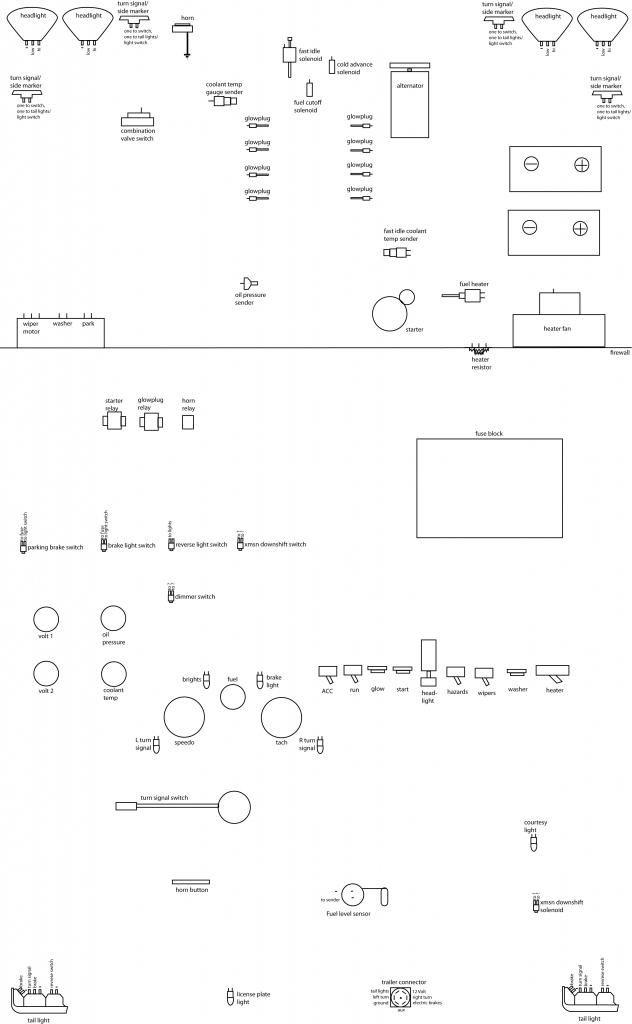

Since I'm going to be starting from scratch, I'm going to engineer in a little extra longevity and reliability. That means relays for all the switches, breakers, a full compliment of useful instrumentation, the whole nine yards. I'm also on a bit of a crusade to eliminate as much plastic from the truck as is practical. That means a custom grille, in which I intend to change up the headlights a bit and add a second set of primary driving lights inboard of the two in the stock position. Finally, and I still haven't fully figured out what and how, but I intend to replace the plasticky stock switches with quality steel rockers where feasible.

I have a few more things to do before I get too deep into this project, but between the weather this coming week and waiting on parts and tools to arrive I will likely be able to find the time to get started on the schematics. I thought it would probably be a process that would be enlightening to some, and maybe even useful, so I'm sharing it here.

On cars where quality aftermarket harnesses are readily available, I'm more than happy to go the easy route. When that's not the case, it becomes necessary to make a harness. This takes longer, but is a lot of fun (assuming you're into that sort of thing) and gives you the opportunity to modify things a bit.

The electrical system on my M1009 is pretty well trashed. Some things sort of work, but I haven't found much electrical that fully works as expected that I didn't recently replace or rebuild myself. Most everything that isn't steel in my truck has all but turned to chalk, so instead of trying to track down and terminate the gremlins one by one just so they can continue to breed and multiply in the chalky insulated recesses of my truck, I'm going to shotgun the thing and make the electrons happy.

Since the civilian harnesses all include power windows and that sort of thing, I really don't care to go that route. The military replacement harnesses will be 30 years old, stiff, and also have a bunch of junk I don't need (the truck is to be a workhorse, occasional off road rig, and occasional daily driver, so blackout lights are kind of silly). I don't think there are any harnesses available for civilian market trucks without any power accessories, AC, and the like. That means I'm pretty much on my own. This is NOT a bad thing!

Since I'm going to be starting from scratch, I'm going to engineer in a little extra longevity and reliability. That means relays for all the switches, breakers, a full compliment of useful instrumentation, the whole nine yards. I'm also on a bit of a crusade to eliminate as much plastic from the truck as is practical. That means a custom grille, in which I intend to change up the headlights a bit and add a second set of primary driving lights inboard of the two in the stock position. Finally, and I still haven't fully figured out what and how, but I intend to replace the plasticky stock switches with quality steel rockers where feasible.

I have a few more things to do before I get too deep into this project, but between the weather this coming week and waiting on parts and tools to arrive I will likely be able to find the time to get started on the schematics. I thought it would probably be a process that would be enlightening to some, and maybe even useful, so I'm sharing it here.