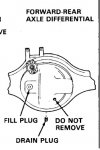

1 - I am confoosed... as usual. I have never done a 5-ton axle, so this is purely a question and not a second guess. Anyway, on all the full floater axles I have done, there is only one inner seal at the back of the hub, and the hub's bearings are lubricated with gear oil. But on this thing you have that outer seal and are packing the bearings with grease. So I guess my question is does the gear oil lubricate the hub bearings at all, or are they completely dependent on the grease you repacked them in? One would think the outer seal is a bad thing since gear oil would be a much better lubricant, and the flange gasket should keep everything in the axle.

2 - Tony, Heavy axles dont lubricate quite like car axles. More like the front on a rear drive car. You MUST pack those bearings well, with a quality qrease. Your Lube Order(LO-9-2320-260-12) calls for GAA which is Grease, Automotive and Artillery(MI1-G-10924) which is Castrol 610, NGLI #2 Grease. Hope this Helps

1 - The MILITARY is who speced the outer seal and GREASE hubs, this was to keep water from getting into the rear chunk area for amphibious operations, the 5t axles ARE wet hub and were used by the civi world for medium to heavy use (cranes, gradealls, drills, ect.) for many years.

You can go back to wet hubs, to do so install NEW ware rings, NEW axle/hub seals, NOT NOS (they tend to be dry and not as flexible), once you change back to wet hubs, you WILL find the the rear hubs WILL run at least 20 deg. COOLER, the reason for this is grease will hold the heat while the hub, and axle housing, act as a heat sink, sucking out the heat from the oil.

Before any of you "experts" call the above BS, take a look in some OLD "Motor Truck Repair Manuals" like #10, this is where I got all the rear ratios, these manuals go into the repair/rebuilding of these axles, also we put this to the test when we RESTORED the restored m62.

2 - This IS 110% FALSE, 99.9% of heavy civi trucks ARE wet hub, The LO calls for grease because of amphibious operations, NOT for the well being of the bearing in everyday operation, as stated above the bearings run hotter in a grease hub. About ALL the NEW front wheel drive trucks (except most military trucks) ARE wet hub also, even some MVs are.

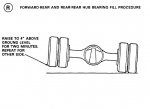

When doing a R/R of a rear wet hub, you pack the hub bearings lightly just so the bearing is lubed till the hub fills with oil. The proper filling sequence for filling a wet hub rear, is to bring the oil level up to the fill plug, take the truck out and do some figure 8s (this fills the hub), bring the truck back and top off the oil level, on front wheel drive wet hubs, there is a hub port like some trailers have that you fill through.