- 2,918

- 9,592

- 113

- Location

- Alexandria, La

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

You are close, only 180 degrees out, the pressure comes from the hydroboost to the winch then to the steeringOk, as I've stated in other threads, the front winch was next.

(Preface... it's CRAZY what you learn AFTER you need to know it. Until this point in my life, I thought all HMMWVs were the same frame etc, just different armor/configurations).

I had bought a 10.5k Mile Marker fron winch that, unbeknownst to me, was for a M998. I was unaware that the REV trucks are 1 1/2' longer.

So.... I blissfully started the process of following the directions and removing what I needed to remove.

View attachment 953332

After fighting the frame extensions, I realized something was off when I could either have the winch sit up front, and none of my lines reached and the control arm bolts didn't reach and the gear controls for the winch.... interfered with the radiator hose..

View attachment 953334

After searching the internet and phoning several friends, I called Mile Marker and landed on the phone with the guy who designed the freaking things!

He explained where I went wrong and I ordered the correct base plate, hoses and frame extensions.

(I test fit it before I started fighting it!)

View attachment 953335

Once I got the correct everything, it was time to put the winch on. Once again, the gear controls were hitting the radiator hose. Another call to Mile Marker and I was told the gear box and hydraulics are run differently on the REV trucks. I needed to spin the winch to move the controls away from the hose. Fortunately, because of my job I am very familiar with re-clocking motors and re-routimg hydraulic lines, so... I spun the motor but now the tubing/hydraulic connections were hitting the radiator hose!

View attachment 953337

I removed the tubing from the motor, ran #6 JIC connection and re-oriented the motor to allow clearance for everything. Then it was a matter of figuring out pressure and flow to the winch. I searched the internet, found some leads but was confused.

ANOTHER call to Mile Marker! (BTW, JR with tech support is AMAZING and PATIENT!).

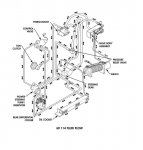

It turns out I was over thinking the problem. He sent me this diagram and explained it to me:

View attachment 953339

Because I already had a rear winch, I could use the pressure side to the steering gear box as a pressure side to the winch. The return line from the winch now went to the steering gear box.

(I'll be posting a "How to" thread shortly. )

Once I got it plumbed up correctly, I connected it electrically (which involved lengthening the wires because, again, wrong kit) and testing it.

View attachment 953342

I used this opportunity to go ahead and spool the wire out all the way as it was coming off the top instead of the bottom.

Once I got it respooled, it was time to mount the heavy.... thing....

With some help from a floor jack and my lovely lady @IRIS_Always we got it mounted.

View attachment 953343

Then it was a matter of mounting the plug...

Fortunately there was already a punch out for it, so I didn't have to drill.

View attachment 953345

The next day, I hooked it to my truck and let it drag the truck back to spool both winches under load.

View attachment 953344

And so now I have 2 fully functional hydraulic winches on the truck!

View attachment 953346

Gotta love the "been there, done that" aspect of this post!! You're a blessed man, Mr. Kendelrio!You are close, only 180 degrees out, the pressure comes from the hydroboost to the winch then to the steering

View attachment 953784

If you have two winches you simply put the two valves in series which is what you did.

Thank you. My brain was absolutely FRIED plumbing that.You are close, only 180 degrees out, the pressure comes from the hydroboost to the winch then to the steering

View attachment 953784

If you have two winches you simply put the two valves in series which is what you did.

You may want to make sure the winch valves are plumbed with the flow in the correct direction, if you have already tested them I doubt they would work installed backwards.Thank you. My brain was absolutely FRIED plumbing that.

They are plumbed correctly. I tested it by unspooling it completely and dragging my Ram 1500 to tighten it.You may want to make sure the winch valves are plumbed with the flow in the correct direction, if you have already tested them I doubt they would work installed backwards.