Update, and some real world testing.

We have the mockup for the cab overhead and rear wall console/storage built, still working on central console mockup.

The Nomadic rooftop AC worked satisfactorily through the summer, though not as well as I hoped. I think

two one issue has affected its performance:

1— our electrical design provided separate truck and accessory circuits built off 4 group 31 batteries. One bank of 2 in series 12v 100ah batteries for each circuit backed up by the 24v 200a alternator. The banks/circuits were separated by a Victron Cyrix 230a combiner. With the 200a alternator backup I grossly underestimated the affect a 100ah AGM battery bank would have on the AC compressor designed for a 400ah system. In testing while driving about town and on the highway the combiner took way too long to connect the circuits/banks together allowing the draw to rapidly lower the 'voltage' near 18.5v in the accessory circuit before connecting. Then once connected the grossly under charged accessory circuit would pull the truck circuit down while the alternator was charging both circuits. The Victron unit sensed this and protected the truck batteries, which of course meant the accessory batteries never fully charged as the truck side drew down below the fail safe point too quickly. This cycle repeated every 20 to 30 minutes. Not a workable design, my fault. I expected the combiner to keep the circuits together much more time. Looking at the Victron spec sheet I should have known better;

2— the Nomadic 24v X3 unit in Max mode pulls about 58a. That's just under 1,400 watts. Which I believe produces just under 4,800 BTU/hour. When we first looked at these units Nomadic's spec sheet stated over 12,000 BTU for the unit. I am not a physics expert, nor an AC tech, but having a built a number of homes over the years I do know how to do the Manual J calcs. 12,000 BTU in the cab is sufficient for comfort even with all the glass. Not enough to make an ice box, but plenty for comfort. So, not being an expert, unless the conversion from watts to BTUs is much greater than 3.412 the Nomadic rooftop unit can't possibly put out 12,000 BTUs. Frankly I was reading the spec sheet and expecting, not inspecting as I should have been. My second mistake. Ronmar put us on the path to the correct BTU formula when looking for cooling air BTU's.

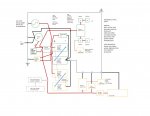

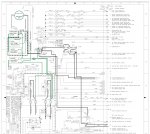

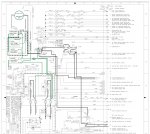

Where are we now? Here is the current electrical layout incorporated into our schematic sheet.

On schematic green wire is new (to be labeled); black is existing or rerouted with labels

1— removed LBCD;

2— removed remote battery disconnect;

3— placed TL 1 (alternator 24v), TL 37 (manual disconnect), and TL507 (inlet air heater) together in a gel sealed weather proof connector;

4— moved TL39 (alternator) to the battery side of the manual disconnect;

5— deleted the 12v path in battery box;

6— added a Victron Orion 24/12-70a dc/dc converter at the passenger footkick;

7— added 12v fuse block to driver foot kick;

8—added a Victron Orion 24/12-70a dc/dc converter at new back wall power center;

9— back wall power center has 1,000w dc/ac converter, 12v fuse block, 24v 60a fuse to AC;

10— added Nomadic 24v X3 rooftop AC to turret panel, we reconfigured the low voltage cutoff parameter to 24v to avoid truck battery draw down.

This configuration will allow the truck to assist the larger habitat system system using Victron Orion-TR Smart dc/dc chargers. Which I believe

@Keith Knight suggested to me over a year ago.

How is it working now?

Over the past month running off 26.8 to 27.5 volts the AC has been much more effective and though I didn't anticipate it the truck seems happier, too. Now when first starting out we put the unit on Max mode, drawing 55 - 58 amps, for about half an hour and then switch to Eco (~33a) or Auto (~45a) modes depending on the outside temperature for the duration of our drive. That typically keeps the interior high 70's to low 80's. We haven't been in temps over 102 as yet, so we will see. The cab insulation isn't yet finished and none of the carpet is in, so this may work long term for our use case.

We are still looking for a complete RedDot Gen2 system and the DC systems are getting better each year. Nomadic has announced they are working to release new mini-split systems (heat and cool) that may have a good sizes for cab and habitat, respectively. We will see what we find as we continue on. (edit) We are getting at least 10,000 BTU's on 24v with <60 amps. (/edit) And I'll be doing my own math for BTU's these new Nomadic units may put out once released.

Also, I am thinking we need to add a fuse (¿225a?) between the batteries and X1 on the PDP.

Comments, suggestions, critiques all welcome. Still evolving the cab and chassis while planning the habitat—