After asking about replacement spring brake chambers or parts and not getting much response, I started to dig into them a little deeper. I read about someone here replacing the diaphragm, but stating it had to go in upside down didn't give me a warm and fuzzy feeling. I called Haldex and talked to a tech that told me parts are no longer available and will no longer be supported. Ryder claimed to have a replacement

which is a Haldex Model 1216012. Upon ordering some, none were in stock and none expected to arrive. I luckily found 4 new ones at a shop and bought them as I had two that were leaking.

I replaced one today and it works fine. The service and emergency ports are in reverse position and only two ports instead of three, but not an issue on our truck.

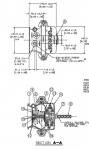

Haldex sent me this drawing, but it's a tad small.

which is a Haldex Model 1216012. Upon ordering some, none were in stock and none expected to arrive. I luckily found 4 new ones at a shop and bought them as I had two that were leaking.

I replaced one today and it works fine. The service and emergency ports are in reverse position and only two ports instead of three, but not an issue on our truck.

Haldex sent me this drawing, but it's a tad small.

Attachments

-

46.9 KB Views: 65