- 1,405

- 590

- 113

- Location

- Quantico VA

I've begun making a soft top for the bed of my HMMWV, in a slant back design. I know that covers exist which extend the roofline back to the tailgate, but I wanted a sloping appearance more like the fiberglass slant backs.

I'm not aware of anyone making or selling these, at least not in a price point I can afford.

Construction is from standard contractor grade 1/2" EMT steel conduit. I'm using standard couplings and a couple of 1/2" iron pipe elbows to serve as the major unions. I've cut apart some screw couplings to serve to join inside portions. I don't know yet how well this will work, but it will be interesting finding out. I'll cover all piping with standard foam pipe insulation to cushion the canvas and give me something wider to wrap velcro straps around. I plan to use the same type of velcro approach as used in the standard soft top, but I don't plan any padding.

My prime reason for making this, besides looking nice, is to keep a majority of rain, debris and snow out of the bed. Given that the M998 HMMWV is a pretty "airy" design, I'm trying to get less water intrusion into the passenger compartment and not have to worry about being parked nose uphill when there is a threat of rain. I now some folks have made bed walls, and that's something else I might could do.

If this works, I may make some to sell, if there is interest. If not, there will be enough pictures at least for someone interested to bash out his own. The sewing will be the hard part, obviously.

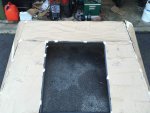

Here are two pictures showing how far I got last evening. All the corners that are taped will be welded this weekend, except the back corners which I am thinking of bolting to the union. I'm trying to make this easy to assemble, with an eye towards possible future sales and being able to ship it rolled up, or just being easy to make for a DIY-er. Some of the necessary unions don't exist in the average Home Depot aisle, so that's where I'm welding. I'm not a stellar welder, so this will be good practice for me. I'm getting better, and the repetition will do me good.

The large cavity in the center will be for a marine vinyl window. I will remove the rear curtain when using the slant back, and plan to get one of the suction cup rear view mirrors from the marine market that some on the site have used with good results. It will be nice to have a rear view mirror to add to visibility in the side mirrors.

Bulldogger

![IMG_0496[1].jpg IMG_0496[1].jpg](https://www.steelsoldiers.com/data/attachments/480/480183-1b7e09986262f24e95002098ac00b8fc.jpg)

I'm not aware of anyone making or selling these, at least not in a price point I can afford.

Construction is from standard contractor grade 1/2" EMT steel conduit. I'm using standard couplings and a couple of 1/2" iron pipe elbows to serve as the major unions. I've cut apart some screw couplings to serve to join inside portions. I don't know yet how well this will work, but it will be interesting finding out. I'll cover all piping with standard foam pipe insulation to cushion the canvas and give me something wider to wrap velcro straps around. I plan to use the same type of velcro approach as used in the standard soft top, but I don't plan any padding.

My prime reason for making this, besides looking nice, is to keep a majority of rain, debris and snow out of the bed. Given that the M998 HMMWV is a pretty "airy" design, I'm trying to get less water intrusion into the passenger compartment and not have to worry about being parked nose uphill when there is a threat of rain. I now some folks have made bed walls, and that's something else I might could do.

If this works, I may make some to sell, if there is interest. If not, there will be enough pictures at least for someone interested to bash out his own. The sewing will be the hard part, obviously.

Here are two pictures showing how far I got last evening. All the corners that are taped will be welded this weekend, except the back corners which I am thinking of bolting to the union. I'm trying to make this easy to assemble, with an eye towards possible future sales and being able to ship it rolled up, or just being easy to make for a DIY-er. Some of the necessary unions don't exist in the average Home Depot aisle, so that's where I'm welding. I'm not a stellar welder, so this will be good practice for me. I'm getting better, and the repetition will do me good.

The large cavity in the center will be for a marine vinyl window. I will remove the rear curtain when using the slant back, and plan to get one of the suction cup rear view mirrors from the marine market that some on the site have used with good results. It will be nice to have a rear view mirror to add to visibility in the side mirrors.

Bulldogger

![IMG_0496[1].jpg IMG_0496[1].jpg](https://www.steelsoldiers.com/data/attachments/480/480183-1b7e09986262f24e95002098ac00b8fc.jpg)