Sparkyz911

Active member

- 65

- 61

- 33

- Location

- Central IL USA

Hope this helps anyone with a starting problem similar to what I just experienced here.

PROBLEM AND DIAGNOSIS

Went out to start the '71 Kaiser. Flipped on the battery disconnect (its wired on ground side) and the dash master switch. Buzzer came on, gauges moved, fuel pump whirring. Hit the Big Red Button and silence. Pump and buzzer shutdown, gauges go flat. Turn off the disconnect, wait a minute and flip back on. Same thing, buzz/move/whir, hit the BRB and silence.

Pull the batteries out and test, 16v/14.5v, together read 25-26v (Batts are at least 3yo). Leave the meter on the batts and proceed with startup, meter reads 26v, hit BRB and 0v. Disconnect off, meter goes back to 26v, turn disconnect right back on and 0v. If I wait a minute or longer then flip disconnect on and 26v til I hit BRB.

After the third attempt I thought I saw very faint smoke come out from under the cab near the batt box/passenger footwell/door area. Since I was sitting center seat I couldn't see exactly from where. No signs of arcing or burns underneath. On all attempts I hear a click or pop that sounds as if its coming from the firewall/floorboard area on passenger side.

Pulled batt box and attempted 4th start attempt. Again, buzz/move/whir, hit BRB and hear click/pop but no smoke/spark/fire. Shut everything down and walked away. Come back couple weeks later (work got in the way) and start up again. THIS time ZZZ-FLASH-POP from battery.

MY SOLUTION IN THIS CASE

Since most starting issues are likely electric related problems I started with the batteries.

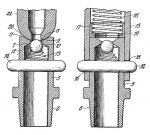

Batts have standard clamp style ends on the inboard end, cap style connectors with a large diameter jumper on the outboard end. The cap style had a side post for the jumper and 2 smaller bolts that press into the post (think like a ceiling fan light sconce). All 3 could be tightened to secure the "cap" to the post. Each cap also had a grease zerk (what kind of grease to use? standard? high heat? dielectric?).

Checked the inboard ends, ground of bat1 was loose, tighten, attempt to start, and ZZZZZZZ-POP-flash from bat2 outboard end again. Pull caps/jumper assembly, and see that bat2 post has some slag on it. No post meltdown yet, but will need new batts by xmas. Cleaned post, caps and reinstall. Started up as normal.

Anyone have similar experiences or solution suggestions (grease type?) please feel free to add on.

PROBLEM AND DIAGNOSIS

Went out to start the '71 Kaiser. Flipped on the battery disconnect (its wired on ground side) and the dash master switch. Buzzer came on, gauges moved, fuel pump whirring. Hit the Big Red Button and silence. Pump and buzzer shutdown, gauges go flat. Turn off the disconnect, wait a minute and flip back on. Same thing, buzz/move/whir, hit the BRB and silence.

Pull the batteries out and test, 16v/14.5v, together read 25-26v (Batts are at least 3yo). Leave the meter on the batts and proceed with startup, meter reads 26v, hit BRB and 0v. Disconnect off, meter goes back to 26v, turn disconnect right back on and 0v. If I wait a minute or longer then flip disconnect on and 26v til I hit BRB.

After the third attempt I thought I saw very faint smoke come out from under the cab near the batt box/passenger footwell/door area. Since I was sitting center seat I couldn't see exactly from where. No signs of arcing or burns underneath. On all attempts I hear a click or pop that sounds as if its coming from the firewall/floorboard area on passenger side.

Pulled batt box and attempted 4th start attempt. Again, buzz/move/whir, hit BRB and hear click/pop but no smoke/spark/fire. Shut everything down and walked away. Come back couple weeks later (work got in the way) and start up again. THIS time ZZZ-FLASH-POP from battery.

MY SOLUTION IN THIS CASE

Since most starting issues are likely electric related problems I started with the batteries.

Batts have standard clamp style ends on the inboard end, cap style connectors with a large diameter jumper on the outboard end. The cap style had a side post for the jumper and 2 smaller bolts that press into the post (think like a ceiling fan light sconce). All 3 could be tightened to secure the "cap" to the post. Each cap also had a grease zerk (what kind of grease to use? standard? high heat? dielectric?).

Checked the inboard ends, ground of bat1 was loose, tighten, attempt to start, and ZZZZZZZ-POP-flash from bat2 outboard end again. Pull caps/jumper assembly, and see that bat2 post has some slag on it. No post meltdown yet, but will need new batts by xmas. Cleaned post, caps and reinstall. Started up as normal.

Anyone have similar experiences or solution suggestions (grease type?) please feel free to add on.