- 574

- -21

- 18

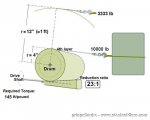

i have a spare deuce winch. i recently bought a gooseneck trailer and i would like to put the deuce winch on it. problem is my trailer doesnt have a multifuel and a spicer 3035 with pto to run my winch  at work i have a hydraulic head thats 12vDC that i can have. i want to couple a hydraulic motor to my deuce winch for the trailer but i need to know how many rpm the winch shaft spins. i know it can be variable speed, but whats the minimum required to operate the winch to its potential. it would be much easier to just put an electric winch on it but im maiking the ramps hydraulic also so why not the winch LOL

at work i have a hydraulic head thats 12vDC that i can have. i want to couple a hydraulic motor to my deuce winch for the trailer but i need to know how many rpm the winch shaft spins. i know it can be variable speed, but whats the minimum required to operate the winch to its potential. it would be much easier to just put an electric winch on it but im maiking the ramps hydraulic also so why not the winch LOL