That appears to be coming from the timing cover under the bracket. No amount of sealant of any kind on the bolt is going to solve that. The oil isn't coming through the threads - it's coming from between the cover and timing case and you can tighten it till you strip it or break it and oil will still find a way through the imperfectly machined surfaces that lack gasket/sealant between them.

For "thread" sealant to work, there must be something you are trying to prevent coming THROUGH the thread - pipe threads are a common situation, or small block Chevy head bolts that thread right into the cooling jacket.... In this case the oil is leaking from something that's being clamped together by the bolt, not from the bolt threads or from under the bolt head.

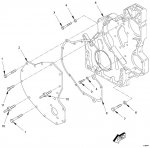

You need to take all that apart and clean it and replace the gasket. Item #8 in this diagram:

You can see that the gasket wraps entirely around that hole so unless it has failed there's no way for oil to get into the hole and leak between the cover and the compressor bracket. My bracket is the same and in the same location and is completely dry around and under that bolt since I installed it in April of 2022.

Indeed you should be able to completely remove that bolt and have nothing happen at all if all the other bolts in that cover are tight and the gasket is in place. That's how I installed my bracket - remove bolt, install bracket, reinstall bolt - no oil was ever present.

The other possibility is that it was over-tightened or bottomed out and the threaded boss in the timing case is cracked or damaged allowing oil into the hole.

View attachment 908427

You will also need #19:

View attachment 908428

And possibly other gaskets and seals.