Jim Layton

New member

- 18

- 14

- 3

- Location

- Saint Petersburg Florida

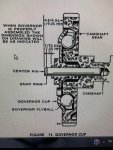

I'm trying to adjust (lower) the rpm on the generator. It is a running unit and will start right up and head for redline rpm until I can get to the governor linkage and hold it at any speed I want. If I let this governor go I believe the engine would rev until it blew up. I have adjusted the cable all the way out, the linkage adjustment all the way out, and the governor arm spring all the way to the bottom as light as it can be. These have made zero change. There seems to be a lot of pressure pulling the governor arm into a wide open position. Do I need to start adjusting linkage down on the fuel pump? I think that is all that is left