-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

MEP-016B Field Flash Procedure

- Thread starter Redokie

- Start date

More options

Who Replied?- 18,063

- 27,093

- 113

- Location

- Burgkunstadt, Germany

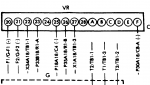

TB1. The long TB in the picture. The last 2 wires on the left side should be F1 and F2. The F1 is positive. Start the set, then apply the DC voltage to F1 and F2 momentarily. Don't get the polarity wrong.

View attachment 915172

View attachment 915171

Ok, I’ve located everything and familiar with the steps.TB1. The long TB in the picture. The last 2 wires on the left side should be F1 and F2. The F1 is positive. Start the set, then apply the DC voltage to F1 and F2 momentarily. Don't get the polarity wrong.

View attachment 915172

View attachment 915171

Do I apply the full 28vdc? I have a variable power supply I can set the voltage and regulate the max amp output.

thanks for your reply.

- 2,918

- 7,101

- 113

- Location

- West greenwich/RI

I don't think you need 28V for field flashing. Some folks use a 9V battery so I'd recommend staying in the 12V and under range first.

- 2,322

- 4,174

- 113

- Location

- Pepperell, Massachusetts

The 9 V battery is a good idea. Lower voltage and it won't put out much current so you don't damage the windings.

- 18,063

- 27,093

- 113

- Location

- Burgkunstadt, Germany

We always used two D cell batteries taped together.

Ok, I’ll start with the D cells and work my way up till I see the desired output and report back.

I have to rig and adjust the governor linkage. I rebuilt the injection pump and have to shift the adjustments towards the shutoff position. She goes to 60hz and starts to climb out, thought I had a runaway for a minute . There is an adjustment screw in the ip outer plunger liner that you don’t touch and I can’t find a TM about the darn thing except overhaul procedures.

. There is an adjustment screw in the ip outer plunger liner that you don’t touch and I can’t find a TM about the darn thing except overhaul procedures.

I have to rig and adjust the governor linkage. I rebuilt the injection pump and have to shift the adjustments towards the shutoff position. She goes to 60hz and starts to climb out, thought I had a runaway for a minute

- 18,063

- 27,093

- 113

- Location

- Burgkunstadt, Germany

Perhaps @Ray70 can shed some light there.

- 2,918

- 7,101

- 113

- Location

- West greenwich/RI

On the IP, you may have reasembled it with the plunger 180* from the alignment marks.

I worked on a 701 years ago ( same engine ) where the governor was acting all kinds of wacky and the thing would not run right... revving up, running away!

Turned out the IP had been gummed up and the owner tried to free it up and somehow got the plunger timing all out of whack such that moving the lever / rack had the opposite effect as it was supposed to.

So trying to increase fuel was actually decreasing it and when the governor tries to decrease fuel it would actually increase it, causing full throttle runaway.

If I recall correctly, the issue was that the barrel is not fixed in position in any real way.

When the pump gummed up, he fiddled with it and broke it free, but also rotated the barrel, essentially causing the timing to go out.

I'd have to go back and research again, but I found the info I needed on you tube by looking up the name of the metering pump. Bosch / Zexel PFR If I recall?

It all came down to making sure the marks were all aligned correctly.

I worked on a 701 years ago ( same engine ) where the governor was acting all kinds of wacky and the thing would not run right... revving up, running away!

Turned out the IP had been gummed up and the owner tried to free it up and somehow got the plunger timing all out of whack such that moving the lever / rack had the opposite effect as it was supposed to.

So trying to increase fuel was actually decreasing it and when the governor tries to decrease fuel it would actually increase it, causing full throttle runaway.

If I recall correctly, the issue was that the barrel is not fixed in position in any real way.

When the pump gummed up, he fiddled with it and broke it free, but also rotated the barrel, essentially causing the timing to go out.

I'd have to go back and research again, but I found the info I needed on you tube by looking up the name of the metering pump. Bosch / Zexel PFR If I recall?

It all came down to making sure the marks were all aligned correctly.

It is a PFR-1K, she was gummed up from sitting 15+ years but fired up without skippingOn the IP, you may have reasembled it with the plunger 180* from the alignment marks.

I worked on a 701 years ago ( same engine ) where the governor was acting all kinds of wacky and the thing would not run right... revving up, running away!

Turned out the IP had been gummed up and the owner tried to free it up and somehow got the plunger timing all out of whack such that moving the lever / rack had the opposite effect as it was supposed to.

So trying to increase fuel was actually decreasing it and when the governor tries to decrease fuel it would actually increase it, causing full throttle runaway.

If I recall correctly, the issue was that the barrel is not fixed in position in any real way.

When the pump gummed up, he fiddled with it and broke it free, but also rotated the barrel, essentially causing the timing to go out.

I'd have to go back and research again, but I found the info I needed on you tube by looking up the name of the metering pump. Bosch / Zexel PFR If I recall?

It all came down to making sure the marks were all aligned correctly.

I got the timing marks lined up on all 3 of the piston components. The outer liner has a small eccentric screw that had a plug over it. The throttle works properly but everything is shifted to a higher setting. I might pull it back out and turn it down. Just have to displace everything to get the covers off for access.

GMG sells a rebuild kit but I need the adjustment instructions for that darn eccentric screw. Till then it’s trial and error.

Update:

I got the engine dialed in and running like a top and attempted the field flash with a 9v battery. No luck.

did some troubleshooting and discovered I have a break in the field stator coil windings. Narrowed it down to 1 of 6 of the coils and have removed the generator stator casing.

Working to pull the main stator to gain access to the field stator without destroying the windings. It’s a tight fit and don’t want to hammer on it too hard. I have access to an industrial oven and going to heat it to 260F to get the aluminum casing to release the iron stator core. Wish me luck or I’m gonna build a diesel powered go kart!….

I got the engine dialed in and running like a top and attempted the field flash with a 9v battery. No luck.

did some troubleshooting and discovered I have a break in the field stator coil windings. Narrowed it down to 1 of 6 of the coils and have removed the generator stator casing.

Working to pull the main stator to gain access to the field stator without destroying the windings. It’s a tight fit and don’t want to hammer on it too hard. I have access to an industrial oven and going to heat it to 260F to get the aluminum casing to release the iron stator core. Wish me luck or I’m gonna build a diesel powered go kart!….

- 18,063

- 27,093

- 113

- Location

- Burgkunstadt, Germany

After reading the first few lines, I started to write about heating. Its the only way to remove AND reinstall the winding's. Or the only way to do it without destroying things. I have used a propane torch to do it also. But that was 30-40 years ago, and no access to an oven.

- 114,062members

- 167,056threads

- 2,351,942posts

- 4,434online users