- 2,114

- 565

- 113

- Location

- Davis County, UT

On December 9th I made a ~6 hour round trip up to Jerome, Idaho and bought from a police officer an MEP-531A he was tired of moving around for years and hadn't had it running in just as long.

Hour meter at time of purchase: 274.9 hours

The front panel needs some repair and it is only held on by two wood screws.

Once home, I tried to use the electric start via slave cables to my MEP-803A. The start switch rotates freely 360 degrees, but I could hear the pre-heat engage when rotated that direction and when turned to start there was only "clicking". I assume there is an issue with the starter or something there.

With verbal instructions from a good friend who already has two of these units, I used a metric socket and loosened the injector and pulled on the manual start cord until fuel started to dribble out. I then re-tightened the injector. After a number of manual pulls (more than I thought it needed), I got the hang of the procedure and the generator fired up and ran! Ambient temperature was about 22F.

About 113v on the terminals and the convenience ports work well, showing about 50% load with both 500W halogen work lights on (~1000W)

Data Plate reads:

GENERATOR SET DIESEL ENGINE 2KW 60HZ

MODEL: ASB 2D / DND7

SER NO: 27B V2

NSN 6115-21-912-0393

REG NO: (blank)

TM TO: (blank)

NAVFAC TM: (blank)

VOLTS: 2KW, 120 VAC, 2 WIRE & GROUND (NEUTRAL BONDED TO FRAME)

AMPS: 18.3 PEAK 16.7 CONT

PF: 1.0

DRY WT: 138.9 LBS

W: 16.0 IN

LG: 29.5 IN

HGT: 21.7 IN

INSUL: CLASS F

TYPE: 3600 RPM, STANDARD SERVICE

FUEL: DIESEL, A/B, F-34, F-35, JP-8

MAX AMBIENT TEMP: 122 ° F

DATE MFG: (blank)

CONTR NO: DAAK01-96-C-0045

MFD BY: MECHRON POWER SYSTEMS INC 35537

WARRANTY: (blank)

DATE INSP: (blank)

INSP STAMP: (blank)

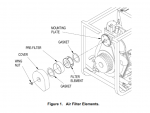

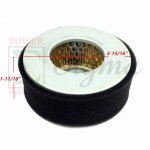

I'm not sure how old it is as the "DATE MFG" is not stamped, but if I had to guess via the Contract Number, perhaps manufactured in 1996. Apparently it is also missing the baffle over the exhaust, and it is in great need of an oil change, new fuel filter, and air filter clean and re-oiled or replaced, (now to search for those part numbers, hah)!

But otherwise, it still seems to be pretty decent condition.

Hour meter at time of purchase: 274.9 hours

The front panel needs some repair and it is only held on by two wood screws.

Once home, I tried to use the electric start via slave cables to my MEP-803A. The start switch rotates freely 360 degrees, but I could hear the pre-heat engage when rotated that direction and when turned to start there was only "clicking". I assume there is an issue with the starter or something there.

With verbal instructions from a good friend who already has two of these units, I used a metric socket and loosened the injector and pulled on the manual start cord until fuel started to dribble out. I then re-tightened the injector. After a number of manual pulls (more than I thought it needed), I got the hang of the procedure and the generator fired up and ran! Ambient temperature was about 22F.

About 113v on the terminals and the convenience ports work well, showing about 50% load with both 500W halogen work lights on (~1000W)

Data Plate reads:

GENERATOR SET DIESEL ENGINE 2KW 60HZ

MODEL: ASB 2D / DND7

SER NO: 27B V2

NSN 6115-21-912-0393

REG NO: (blank)

TM TO: (blank)

NAVFAC TM: (blank)

VOLTS: 2KW, 120 VAC, 2 WIRE & GROUND (NEUTRAL BONDED TO FRAME)

AMPS: 18.3 PEAK 16.7 CONT

PF: 1.0

DRY WT: 138.9 LBS

W: 16.0 IN

LG: 29.5 IN

HGT: 21.7 IN

INSUL: CLASS F

TYPE: 3600 RPM, STANDARD SERVICE

FUEL: DIESEL, A/B, F-34, F-35, JP-8

MAX AMBIENT TEMP: 122 ° F

DATE MFG: (blank)

CONTR NO: DAAK01-96-C-0045

MFD BY: MECHRON POWER SYSTEMS INC 35537

WARRANTY: (blank)

DATE INSP: (blank)

INSP STAMP: (blank)

I'm not sure how old it is as the "DATE MFG" is not stamped, but if I had to guess via the Contract Number, perhaps manufactured in 1996. Apparently it is also missing the baffle over the exhaust, and it is in great need of an oil change, new fuel filter, and air filter clean and re-oiled or replaced, (now to search for those part numbers, hah)!

But otherwise, it still seems to be pretty decent condition.

Last edited: