Raphael

New member

- 12

- 0

- 0

- Location

- Carrollton/Ohio

Hi - This is my first post!!! Please be patient - I'm not yet up to speed .

.

OK, we bought 2 MEP-803A, one runs fine, the other doesn't. Here is what happened:

I started the engine up and for about 10 sec. the voltage was normal and the frequency showed around 60Hz. Then the voltage dropped to 0V and the frequency went all the way down (I mean the Hz meter). I found, that the quad fuse was blown.

Since then I changed the frequency module A7 and the voltage regulator (we have 2 gen-sets) but it didn't help. I can change the fuse and it works for some time. The frequency keeps at the lowest setting at the meter. I found out, that the quad current is around 1Amp at 220V (L1-L3) (I run the unit at 120/240) but it increases very much when I do want to get up to 240V, where it should be. It is around 5A or higher. It seems that somehow the generator doesn't reach the output voltage and the voltage regulator cranks up the current, until the fuse blows.

We had a 3kW heater connected to it and it worked. Only I can't get up to 240V without the fuse blowing.

Here is another strange thing about the generator. I can measure a current at each of the wires coming out of the generator head without anything connected to it. Around 0.4-0.5A. I don't know where this goes - or is it reactive?

The generator was somehow modified. The diagnostic outlet was changed for a remote monitor outlet. (The diagnostic plug dangles inside...). There is written that before starting the remote monitor cable or the loop back plug should be attached. And there is a modification at the voltage reconnection switch. Where normally is the position for 220/208 and 120 is written do not use and at the 120/240 position is written: shadow CGS. I have no idea, what that is about.

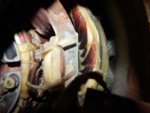

And it may be good to know, that the generator housing is damaged. It somehow fell at some time. Maybe that is important too?

I would appreciate any kind of help.

Thank you!

OK, we bought 2 MEP-803A, one runs fine, the other doesn't. Here is what happened:

I started the engine up and for about 10 sec. the voltage was normal and the frequency showed around 60Hz. Then the voltage dropped to 0V and the frequency went all the way down (I mean the Hz meter). I found, that the quad fuse was blown.

Since then I changed the frequency module A7 and the voltage regulator (we have 2 gen-sets) but it didn't help. I can change the fuse and it works for some time. The frequency keeps at the lowest setting at the meter. I found out, that the quad current is around 1Amp at 220V (L1-L3) (I run the unit at 120/240) but it increases very much when I do want to get up to 240V, where it should be. It is around 5A or higher. It seems that somehow the generator doesn't reach the output voltage and the voltage regulator cranks up the current, until the fuse blows.

We had a 3kW heater connected to it and it worked. Only I can't get up to 240V without the fuse blowing.

Here is another strange thing about the generator. I can measure a current at each of the wires coming out of the generator head without anything connected to it. Around 0.4-0.5A. I don't know where this goes - or is it reactive?

The generator was somehow modified. The diagnostic outlet was changed for a remote monitor outlet. (The diagnostic plug dangles inside...). There is written that before starting the remote monitor cable or the loop back plug should be attached. And there is a modification at the voltage reconnection switch. Where normally is the position for 220/208 and 120 is written do not use and at the 120/240 position is written: shadow CGS. I have no idea, what that is about.

And it may be good to know, that the generator housing is damaged. It somehow fell at some time. Maybe that is important too?

I would appreciate any kind of help.

Thank you!