-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

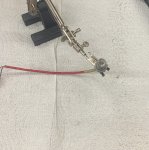

Mag Pickup repairs on my MEP804 a

- Thread starter a3944296

- Start date

More options

Who Replied?- 4,518

- 2,606

- 113

- Location

- East of Edmond, Oklahoma

Post your needs in the Parts Wanted forum.

I'm sure you already looked in the TMs for the NSN and civilian part number.

I'm sure you already looked in the TMs for the NSN and civilian part number.

- 2,324

- 4,178

- 113

- Location

- Pepperell, Massachusetts

Search MSP6729 3/8”x24 around $20.

Another S.S. member purchased it for their 804.

804 MPU See post #7

Another S.S. member purchased it for their 804.

804 MPU See post #7

LuckeyD

Well-known member

- 115

- 341

- 63

- Location

- Vilseck, Germany

Good Day: The TM says install till it bottoms on the toothed flywheel with the tip usually between 2 teeth and back out till you get 2VAC. Uh, we found if you bottom out turn it back about 4 turns, then using dead crank as you screw it in slowly obtain your AC and snug the locknut and don't Baby Huey it. Now connect after rechecking and you are about good to go. These guys also pick up metal shavings over time from starter and flywheel and eventually fail from that and garbage in the bellhousing. There is no repair we could figure out. The one on my Crossfire also just suddenly stopped working in the middle of traffic so they do fail for no reasons with time. Wish you luck.

Good Day: The TM says install till it bottoms on the toothed flywheel with the tip usually between 2 teeth and back out till you get 2VAC. Uh, we found if you bottom out turn it back about 4 turns, then using dead crank as you screw it in slowly obtain your AC and snug the locknut and don't Baby Huey it. Now connect after rechecking and you are about good to go. These guys also pick up metal shavings over time from starter and flywheel and eventually fail from that and garbage in the bellhousing. There is no repair we could figure out. The one on my Crossfire also just suddenly stopped working in the middle of traffic so they do fail for no reasons with time. Wish you luck.

reset2

Active member

- 199

- 101

- 43

- Location

- Myersville MD

Use alligator clips on your multi meter and face it towards the dead crank switch. Watch the multi meter as cranking. Also follow the TM procedure to the letter for setting. I thought I would save time and turned the MPU in 1/4, 1/2 turn at one point of adjusting and then heard the tip getting ground off. Lesson learned. Get the voltage in range and stop.

Sent from my SM-G781U using Tapatalk

Sent from my SM-G781U using Tapatalk

LuckeyD

Well-known member

- 115

- 341

- 63

- Location

- Vilseck, Germany

Well, you can try the procedures starting on page 2-306 and ending on page 2-307 and hopefully that one turn will clear the flywheel teeth, but take it from one of the folks that traveled the planet and 11 years in war zones doing the same, use alligator clips at the pickup to your meter set to read AC voltage, all by yourself; bottom out the pickup, back it off 3-4 turns (always clears the flywheel teeth), and now while measuring, SLOWLY turn it in till you get about 2.5VAC, using the dead crank switch. Snug up and RECHECK for about 2.5VAC. Now plug in the wiring to the control panel. I did thousands like this and never had an issue, while units said they followed the manual with several pick ups.

The 804 and most A model TQGs work well with 2.5 VAC. B models 30 and 60KW are set to 1.6VAC, and you turn into a pretzel doing it. If you set too high an AC Voltage you overdrive the Governor control and the gens do funny things.

Also if the gen starts and runs fine, leave this thing alone. They last longer this way. Your choice. when completed, now set control panel FREQ adjust in the middle and adjust in the Governor control using a meter that reads frequency and AC Voltage. I attached a cheat sheet I made up in the early 2000s used by many Soldiers and LARs. It was never supposed to be a manual replacement and I reference manual passages so one may also check.

The 804 and most A model TQGs work well with 2.5 VAC. B models 30 and 60KW are set to 1.6VAC, and you turn into a pretzel doing it. If you set too high an AC Voltage you overdrive the Governor control and the gens do funny things.

Also if the gen starts and runs fine, leave this thing alone. They last longer this way. Your choice. when completed, now set control panel FREQ adjust in the middle and adjust in the Governor control using a meter that reads frequency and AC Voltage. I attached a cheat sheet I made up in the early 2000s used by many Soldiers and LARs. It was never supposed to be a manual replacement and I reference manual passages so one may also check.

Attachments

-

306.2 KB Views: 5

- 114,103members

- 167,071threads

- 2,352,251posts

- 2,689online users