Ok, new bushing is into the assembly. One of the short case bolts ripped out its threads as I removed it, so I am going to tap and install a 12mm bolt then I can re-assemble the P6…

While I was looking thru as much of the assembly as I could access trying to fully understand it, I came to realize that the center clutch disc carrier cannot move as far forward as I initially measured, as the main front snap ring and compressed discs do not limit the forward travel of the center carrier, the center shaft does. I came to realize that if it did move as far as the snap ring and discs allow, with the center carrier pulled all the way forward with discs compressed against the snap ring, even the 8.5MM/.335” thrust bushing could still slide far enough forward to fall off of its perch on the center spindle.

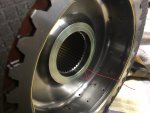

So I looked around a little more and went out and installed the clutch carrier onto the splined center shaft and pushed it all the way forward. At the front of the splines on the shaft there is a raised step. The long snout on the clutch carrier contacts this, stopping its forward travel before the curved/flaring base of the carrier snout contacts the bearing cover plate… in this full forward position, using a straight edge, I measured from the front face of the disc carrier to the gasket face where the p6 cover bolts on. It was right at .750”

I re-assembled the carrier and clutch discs back into the case resting on the new .335” thrust bushing. Using a straight edge I again measured the distance between the front of the disc carrier and the gasket face on the P6 housing… this worked out to be right at .800” in light of this revelation the bushing cannot come off its center carrier perch. And it appears that with the new bushing in place, the disc carrier has ~.050” of free travel. It also means that with the original ~3.5mm(.138”) roller thrust bearing, the carrier had ~.247” of free travel…

So what causes this roller bearing failure? Repeated tapping of clutch and carrier against roller bearing? Repeatedly accelerating the bearing from a standstill with each contact? or as 87CR250R indicated, only lightly loading the bearing? or perhaps all of the above… Looking at the configuration, it probably should have been a thrust bushing in the first place… the failures appear to be low and random, but they do fail…

has anyone heard or seen a failure with the second roller thrust bearing Allison specified?

Anyway, time to re-assemble.

FWIW…