- 2,131

- 605

- 113

- Location

- Davis County, UT

I have thought about it, but I really don't want to manually turn on and off the air compressors, each and every time they need to run. Besides, that wouldn't add the 100 times complexity that wheelspinner said it would.Have you considered using this setup basically as is? Mount the switch in your truck and use it manually. Maybe add a bright light for a reminder that it's on?

Now that I know that the breakers are auto resetting, it does make me want to use them - that's a LOT nicer than a fuse, but I would still like a power distribution box for my various electronics (fans, light bar(s), air compressors, interior lights etc) to clean up my battery box and numerous in-line fuses (future and current)!

I will update this list (as long as I am able to) with product links or as the design changes:

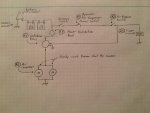

Here is my current design. I'm no gringeltaube to make very nice, precise, digital schematics. When needed, I just hand draw my schematics.

Note: This depicts electrical connections only. Air connections are implied.

As can be seen by this design, my intent is two fold, 1) The operator has the ability to turn on/off the electrical air compressors at will, 2) The ability to control/power the electrical air compressors can only happen when the in-cab Accessory Switch is switched on.

Parts list:

#1: Operator Manual Control

What I want here is to be able to turn on or off the air compressors as desired. Example: I don't want the air compressors to turn on when I'm trying to start the truck. However, I don't want a simple on/off switch like what came with the compressor assembly; I want this switch to always start in the off position so any operator cannot forget and leave the air compressors powered (assuming the operator turned off the Accessory Power lever switch). This means that a simple toggle switch will not do. I need a switch that will self turn off when it looses power.

Said function was harder to find than I expected, and I wasn't able to find it integrated into a single lever switch.

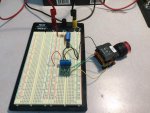

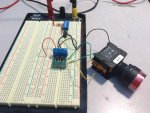

So I ordered this Pololu board that will perform my required operation, rated for 4.5V through 40V:

Big Pushbutton Power Switch with Reverse Voltage Protection, HP

https://www.pololu.com/product/2813

"The Pololu Pushbutton Power Switch is a compact, solid-state power switch that features built-in reverse-voltage protection and is controlled by a momentary pushbutton: one push turns on power and another push turns it off. This is a patented design initially created for use in our own products as an alternative to bulky mechanical switches. Because the switched current does not flow through the mechanical switch, a large variety of small, low-power switches can be used to control a substantial amount of power. The use of momentary switches also allows multiple switches to be used in parallel to control the power to one load."

A momentary pushbutton is needed to turn the control on or off, and when power is lost to the Pololu HP board, at 28V it should start in the "off" state.

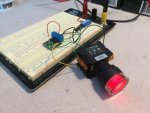

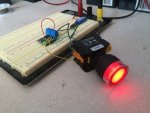

I had considered a button and a military indictor lamp, but I wanted a self-lit, LED button. The LED would only be powered when the Pololu HP board's "VOUT" is powered.

I liked the following button because it had screw terminals and an interesting modular design. It even appears to have a replaceable LED lamp.

Alpinetech LXG-22 Red 22mm 1NC Momentary Push Button

https://www.amazon.com/gp/product/B00FOU7H0M/

However, I couldn't find the above in both red and NO (Normally Open). A feature of the modular design is that I can replace/add the default NC (Normally Closed) portion of the above switch with this NO contact block:

Alpinetech Normally Open NO Contact Block

https://www.amazon.com/gp/product/B00IJ4FIZ6/

I will seal the circuit board with:

CRC Urethane Seal Coat Viscous Liquid Coating, 250 Degree F Maximum Temperature, 11 oz Aerosol Can, Clear

https://www.amazon.com/gp/product/B000IC7ZQ2/

#2: Air Pressure Switch

The air pressure switch will toggle itself as the air pressure changes, but electrical control will only flow to the (#4) Continuous Relay if the (#1) Operator Manual Control is enabled.

85 PSI on, 105 PSI off Pressure Switch Part# 002-105

https://www.extremeoutback.com/product/55/105psi+Pressure+Switch+++++Part#+002-105.html

It would be easiest to mount this on an airline in the cab due to the (#3) Timer (less wire routing).

#3: Timer

I want to know how long the air compressors have run, so as problems/wear occurs I can get an accurate runtime measurement. I do not believe the above Pololu board or the truck's Accessory switch would have any problems powering the addition of the timer.

I want the timer collocated with the (#1) Operator Manual switch, near the instrument cluster. I believe I will mount the button, small circuit board, and timer to the left of the front axle engage lever.

Neecooler Hour Meter DC 10V-80V Mechanical Hourmeter Gauge [SYS-1 ]

https://www.amazon.com/Neecooler-10V-80V-Mechanical-Hourmeter-Motorcross/dp/B01EJFEFH0/

A round option:

Round Hour Meter Gauge Quarzt OZ-USA® 12-24-48 Volt Golf Cart 48V 24V 12V Cat Komatsu RV

https://www.amazon.com/gp/product/B00C0SQUZE/

#4: Continuous Relay

Since I do not want to manually control each and every run of the electrical compressors via the large, manual switch that came with the air compressor cage, a relay is needed to supply the necessary current to the air compressors' electrical motor. The said relay needs to be able to continuously operate at the steady, maximum amperage draw of the air compressors (24A single, 48A pair)

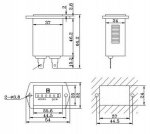

I ordered Extreme Outback's nice, sealed version:

100 Amp Continuous Relay Part# 002-240, $36.95

2A activation/control draw

NOTE: The below link is the 12v version:

https://www.extremeoutback.com/product/97/100+Amp+Relay+Part#+002-103.html

For note for others: a possible cheaper option:

85A Solenoid for Golf Cart & Heavy Duty Industrial Applications 24 Volt Continuous Duty

https://www.amazon.com/gp/product/B004V3FGOC/

#5: Power Distribution Panel

It would be nice to have all accessories lead back to one box, instead of an ungainly mess bolted onto one battery terminal with inline fuses everywhere.

Albeit pricy, this sort of 2-in-1 fuse block combines both heavy current and lighter current applications. PERFECT for this and my other electrical needs.

Blue Sea Systems SafetyHub 150 Fuse Block

https://www.amazon.com/Blue-Sea-Systems-SafetyHub-Block/dp/B0053BTSEK/

Due to Amazon's price, I actually ordered from here:

http://www.defender.com/product.jsp?path=-1|328|2290021|2290030&id=1527942

I decided on a 70A fuse for the relay, even though the motors should never pull more than 48A continuous. Just so there was a enough peak buffer.

Blue Sea Systems AMI/ MIDI Fuses

https://www.amazon.com/gp/product/B004ZJ0RL4/

Overall Specifications:

http://catalog.bluesea.com/#65/z

Amperage Max. Operating (combined) 280A

Minimum Cable Size to Meet Ratings 4/0 AWG (120 mm²)

Recommended Ring Terminal M8 (5/16") Stud Size

M8 MIDI® or AMI® Fuse Block

Amperage Max. Operating (per block) 280A

Amperage Max. Operating (per circuit) 170A

Fuse Amperages Available 30A–200A

Minimum Cable Size to Meet Ratings 2/0 AWG (70 mm²)

Screw Size M5

ATO® or ATC® Fuse Block

Amperage Max. Operating (per block) 50A

Amperage Max. Operating (per circuit) 25A

Fuse Amperages Available 1A–30A

Screw Size #8-32

A lower cost alternate option that would require two relays:

Blue Sea Systems ST Blade ATO/ATC Fuse Blocks

https://www.amazon.com/dp/B000THQ0CQ/

#6: Air Compressors

To complete the air compressors and make them functional with the system:

Two of High Temperature Check Valve Part# 002-097

https://www.extremeoutback.com/product/61/High+Temperature+Check+Valve+Part#+002-097.html

New, foam, pre-oiled air filters Part#: 002-102 ($24.94 each)

I was told the following:

These military compressors are a bit different than the ones on the website with the pre-cleaner. You must call to order the foam air filter. Use only foam filter oil (not K&N oil), but chainsaw bar oil would work too. The foam filters cannot be too oily as the excess will only drip away. If the filter is dry, then it's not working. Even if it's muddy, if its still oily, it's fine.

Notes

I spoke with George Carousos. He was very, very personable, and helpful in everyway.

EXTREME OUTBACK PRODUCTS

www.extremeoutback.com

866-447-7711 Toll Free

707-447-7711 Direct

707-447-7722 Fax

Last edited:

or AMI

or AMI