- 2,113

- 563

- 113

- Location

- Davis County, UT

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

For on road driving the stock air compressor is adequate. When we were offroading the stock setup could not keep up with his air requirements in the more technical areas. Never ran out but was low enough to be a concern.I have air assisted steering on my deuces. And the M45 530C fire truck. I have an additional deuce air tank underneath, and have the ability to 'lock to lock' steer (stationary) on hard standing with two fingers.

OK, it takes longer to air up, but that is well within the pr-warm up and walk round before I drive off anyway. All pressures set to 120 P.S.I.

I'm not irritated, but I was just wondering why he went this much more expensive route instead of just adding an extra air tank.For on road driving the stock air compressor is adequate. When we were offroading the stock setup could not keep up with his air requirements in the more technical areas. Never ran out but was low enough to be a concern.

No clue why so many of yall are irritated by this mod. It's to supplement the air requirements, not replace the mechanical compressor.

Added volume doesn't eliminate the need to stop often to re-supply when offroading. Reduces the amount of stops required yes but doesn't eliminate it and makes those stops longer. There's alot of technical offroad terrain here where you will turn from lock to lock repeatedly within the length of the truck moving forward. Even at just 1st gear, low range, 1000rpm driving speed it was a problem for him. There is much more technical trails in this area to explore as well. A higher output air compressor is what's necessary here. Could find a way to mount a more powerful engine driven compressor, 2nd one, or electric to meet those requirements.I'm not irritated, but I was just wondering why he went this much more expensive route instead of just adding an extra air tank.

I'm not irritated, but I was just wondering why he went this much more expensive route instead of just adding an extra air tank.

And your comments help the discussion how ?Because... he can!

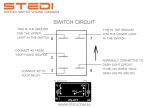

Excellent work as always!....I have to say, so far I'm really impressed with the Wirefly wire connectors that are also heat shrinkable and have heat activate glue sealant!

https://www.amazon.com/gp/product/B01GXQMP66/

View attachment 679154....

I also wanted to report, that after two days and one press of the brake pedal, the truck still registered 60 PSI in the system.A third leak test resulted in NO leaks, and I disconnected the shop air from the truck. Three hours later the needle on the air pressure gauge in the cab still (nearly) read 120 PSI. SUCCESS!

We get it, advertisements are annoying!

Sure, ad-blocking software does a great job at blocking ads, but it also blocks useful features of our website like our supporting vendors. Their ads help keep Steel Soldiers going. Please consider disabling your ad blockers for the site. Thanks!