spicergear

New member

- 2,307

- 26

- 0

- Location

- Millerstown, PA

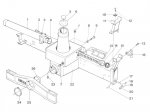

I can pleasantly state that I feel very good progress is being made! As of today, 02/05/06, it's been about a month. This is solid weekends and picking at little things evenings for a couple hours after a long drive up from work. On the HEMMT, this sucker mounts at the rear of the truck with the frame sandwiched between the crane and the outrigger body (under) and that was quite simple. I mid mounted this deal and had to do some extensive mods to outrigger because mounting it below the frame was out of picture since there's this drive shaft thing there that can't too easily be moved. The outrigger has a big single cylinder in it also, so it couldn't be cut or notched for the driveshaft...nor could it be spaced down to clear driveshaft as it would have just been real dumb looking then...and like a literal foot off the ground.

I decided to mount it behind the cab and flip the body of it. This required having to disassemble it completely, cut out some of the internal mounts for the ends of the ram, make up new mounting connections and weld them in all working through some pretty confined areas. All this crap is REAL heavy too. I chose to gusset the now top of the outrigger body in the same way the GROVE originally did when they designed it. When I picked up the crane some bartering had been done by the great people I had gotten it from (THANK YOU REED CLAN!!!) when they picked it up and they snagged me an extra base with mounts. I used one of those 'spare' mounts for the driver's side mount of the outrigger. The pass side mount was...interesting. There's this pesky fuel tank there that I did not look forward to having to relocate. I instead, used a hunk of 4"x 6" x 3/8" angle, braced it with 3/8"x 2" flat bar and did it in a way that it could be sandwiched between the original tank mouts and the frame then the outrigger could bolt down to it and the tank moved only like 5/8" straight out off the frame. The mounts, of course, don't have bolt holes in the right location for the deuce frame so I had to redrill. I have seven, 5/8" GRD 5 bolts per side cinching it to the frame, and four 5/8" bolts per side holding the outrigger assy down to them. On the ends of the mounts facing the rear I bored another two large bolt holes.

Crane base was done in very similiar fashion. 7 per side, then the factory four 7/8" monsters holding the crane to the mounts. Yeah...I'm tightening all this crap with a 3/4" breaker bar. I drilled all the holes to size. 5/8" hole, 5/8" bolt. Drilling all the holes took time off of my lifespan. Each hole is 3 drill sizes the third being 5/8" hanging on an evil old drill with a pair of handles to try and hang on to it. Had to put a little notch in the crossmember just ahead of the middle axle for the one detent in the 'swing' hydraulic motor. Oh and beside having 28 bolts holding these two to the frame, there four more 5/8" bolts bolting each side mount together. I figured that ought to be pretty substantial.

Needed a nice hydraulic tank. 10 would do...but my gut wanted more capacity. A buddy got a Case model 406 'Mog and took off the twin 20 gallon air tanks it was equipped with. I snagged them and will run one for air and the other for hydraulic oil. They could not have fit any better if I had specified them to be built! Yes, lucked out- I mounted them on some pretty burly mounts, that incorporated some of the 'mog mounts, on top of the outrigger just behind the cab. Mounts are 4"x6" angle base with 3x3x 1/4" post then 2x2x1/4" supports, then another mounting point above that. I've also just gotten the full rack of valves mounted on the driver's side behind the outrigger. Don't have a pic of the valves mounted yet...but I think one pic has if mocked up. Looks like I'll be cutting down dropside from 12' to 9' before it goes back on...but that's still down the road. Next project is pluming tanks and mounting hyd pump while keeping in mind I still gotta get a shaft back to the rear winch. I REALLY like winches to be mechanical, even though HYD would be quite easy. I'm not smart like that-

This is just after another crane *placed* this crane on the truck. It move about 14" forward from the first pic.

I decided to mount it behind the cab and flip the body of it. This required having to disassemble it completely, cut out some of the internal mounts for the ends of the ram, make up new mounting connections and weld them in all working through some pretty confined areas. All this crap is REAL heavy too. I chose to gusset the now top of the outrigger body in the same way the GROVE originally did when they designed it. When I picked up the crane some bartering had been done by the great people I had gotten it from (THANK YOU REED CLAN!!!) when they picked it up and they snagged me an extra base with mounts. I used one of those 'spare' mounts for the driver's side mount of the outrigger. The pass side mount was...interesting. There's this pesky fuel tank there that I did not look forward to having to relocate. I instead, used a hunk of 4"x 6" x 3/8" angle, braced it with 3/8"x 2" flat bar and did it in a way that it could be sandwiched between the original tank mouts and the frame then the outrigger could bolt down to it and the tank moved only like 5/8" straight out off the frame. The mounts, of course, don't have bolt holes in the right location for the deuce frame so I had to redrill. I have seven, 5/8" GRD 5 bolts per side cinching it to the frame, and four 5/8" bolts per side holding the outrigger assy down to them. On the ends of the mounts facing the rear I bored another two large bolt holes.

Crane base was done in very similiar fashion. 7 per side, then the factory four 7/8" monsters holding the crane to the mounts. Yeah...I'm tightening all this crap with a 3/4" breaker bar. I drilled all the holes to size. 5/8" hole, 5/8" bolt. Drilling all the holes took time off of my lifespan. Each hole is 3 drill sizes the third being 5/8" hanging on an evil old drill with a pair of handles to try and hang on to it. Had to put a little notch in the crossmember just ahead of the middle axle for the one detent in the 'swing' hydraulic motor. Oh and beside having 28 bolts holding these two to the frame, there four more 5/8" bolts bolting each side mount together. I figured that ought to be pretty substantial.

Needed a nice hydraulic tank. 10 would do...but my gut wanted more capacity. A buddy got a Case model 406 'Mog and took off the twin 20 gallon air tanks it was equipped with. I snagged them and will run one for air and the other for hydraulic oil. They could not have fit any better if I had specified them to be built! Yes, lucked out- I mounted them on some pretty burly mounts, that incorporated some of the 'mog mounts, on top of the outrigger just behind the cab. Mounts are 4"x6" angle base with 3x3x 1/4" post then 2x2x1/4" supports, then another mounting point above that. I've also just gotten the full rack of valves mounted on the driver's side behind the outrigger. Don't have a pic of the valves mounted yet...but I think one pic has if mocked up. Looks like I'll be cutting down dropside from 12' to 9' before it goes back on...but that's still down the road. Next project is pluming tanks and mounting hyd pump while keeping in mind I still gotta get a shaft back to the rear winch. I REALLY like winches to be mechanical, even though HYD would be quite easy. I'm not smart like that-

This is just after another crane *placed* this crane on the truck. It move about 14" forward from the first pic.

Attachments

-

191.9 KB Views: 1,716

-

210.6 KB Views: 1,739

-

264.6 KB Views: 1,722

-

217.4 KB Views: 1,698

-

205.8 KB Views: 1,682