OldDominionIron2

New member

- 100

- 1

- 0

- Location

- Hampton, VA

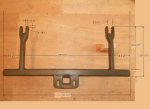

Like I said before, I love the way this mount looks, and there's no doubt it's solid. That being said, someone else had pics of their hitch, and it had a 2" receiver tube welded to the back bumper for vertical support. I like having the two vertical supports of this design, and am wondering about using two receiver tubes welded to the bumper to insert the vertical bars into. Food for thought....I'd like to keep the shackle points available for shackles.

All kidding aside, excellent fab work, 1st rate.

All kidding aside, excellent fab work, 1st rate.