The Final Teardown

Well I got back into it today. The gantry came in with the 1 ton trolley and the 350/700KG cable lift. I know why people choose chain lifts....the cable can be a hassle when it does not want to wind correctly. Anyways, got the second genset off the truck and off to the side. The motor and generator from the first set, the one this thread is about, got put on the back of the PU truck once pulled from the housing to work on and take apart. Took it all the way down including the removal of the crankshaft and bearings. Came apart relatively easy with no major issues, not even a minor issue. Generator separated from the engine just fine as well.

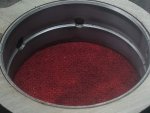

BTW, the generator was full of a very small particulate dust, smaller than talcum powder, almost like confectioners sugar. Had a slight pink color to it. Everywhere inside the generator. Spent some time cleaning it out and getting all the dust out as possible. There was some rust spots on the stator, exciter, and rotor. Cleaned up the rust with ease.

Take a look at the main bearings.....lots of scarring on these as well and some odd wear. The amount of RTV cement and where it was used continues to astound me. Looks like there was a leaking main bearing, flywheel end, and it looks like it was sealed with RTV. Check out the pics, make your own decision.

The block and crank and cam shafts are all in specs, down to .001in, with most being exactly on. Again, what I'd expect to find out of a box. There is evidence that this is the 3rd rebuild (4th really if you count the two the seller had his mechanic do) in that there is engine marking paint in green, white, and now my chalk. I think this was a TIER rebuild of the engine (green paint), then the seller did the rebuild (white paint), and now my rebuild. It would explain the low hours on the 2009 set (218 hours) and also explain the amount of powdered dust there is in the generator itself. However, there is no plate indicating a TIER rebuild, just a CECOM Tier poster on the side of the genset in one of the original pictures from last year.

Now to find the tools to extract and replace the three bearings that specialty tools are needed. Camshaft bearing, crankshaft bearing gear end, and crankshaft bearing flywheel end.

Anyways, some more photos to look over.

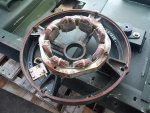

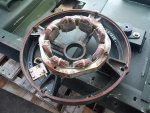

Generator stator, rotor, and exciter. Looks like some oil leakage at the bottom of the generator at the flywheel end of the engine.

Flywheel end main seal and bearing cap. Look at all the RTV cement.

More evidence of leakage from the flywheel end bearing/seal...

Camshaft bearing.

More to come.