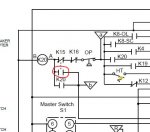

I just bought a 803a that has a burnt up ground wire. It is burnt up from the tb4 9 through the power connector and then on the 8. Some of the wires that were around those wires had some burning but they look clear to me that they weren't the problem, just collateral damage. My question is does anybody have any suggestion or reasoning as to why this might have burnt up. It looks like it's just a ground wire. Also, can somebody explain to me the k20 circuit, does power come from that triangle a because I can't find where another triangle a anywhere. Also the triangle b looks like it goes to ground on tb2. Is that correct? Seems like a short to me. Generator only has roughly 300hrs so I'm hoping it's not going to be too bad getting it going.

Thank you in advance!

Brandon

Thank you in advance!

Brandon

Attachments

-

96.2 KB Views: 39

-

99.1 KB Views: 40

-

72.2 KB Views: 40

-

62.8 KB Views: 40

-

60.1 KB Views: 40

-

60.7 KB Views: 40

-

101.4 KB Views: 40

-

105 KB Views: 39