-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

'90 BMY - stumbles/cuts out on acceleration

- Thread starter MontanaBighorn

- Start date

More options

Who Replied?- 26,246

- 1,193

- 113

- Location

- NY

Here's a cross refrence chart for it.

http://www.donaldsontoolbox.com.au/search/partdetail/equivalentparts/P550316/

http://www.donaldsontoolbox.com.au/search/partdetail/equivalentparts/P550316/

MontanaBighorn

New member

- 16

- 0

- 0

- Location

- MT

So I removed and replaced both fuel filters. I filled both filters with Sea Foam before reinstalling them and cranked the truck. It idled just fine for a minute or two and then it cut off and won't start back. It would lead me to believe that it's not priming itself. Any quick tips I can try to get it primed? I know all the answers are in the manual but I just don't have time to read it all right now.

Thanks,

Thanks,

tomcata3

Member

- 151

- 2

- 18

- Location

- spring city, pa

crack the bleeder screw near injectors and uses the manual prime near fuel filter

MontanaBighorn

New member

- 16

- 0

- 0

- Location

- MT

Thanks for the responses. I refilled the canister and cranked the truck again. It has continued to run this time, no bleeding required.

At this point I'm ready to go into the testing phase to find out if the cutting out was the result of the filters (there was considerable nasty rust and gunk in the bottom of the canister) or if my first impression was right (lift pump going bad). Its way too dark and cold to take it out tonight; I would hate to break down on a night like this. I'll test it tomorrow.

Thanks again, all.

At this point I'm ready to go into the testing phase to find out if the cutting out was the result of the filters (there was considerable nasty rust and gunk in the bottom of the canister) or if my first impression was right (lift pump going bad). Its way too dark and cold to take it out tonight; I would hate to break down on a night like this. I'll test it tomorrow.

Thanks again, all.

- 3,754

- 1,539

- 113

- Location

- North Carolina - FINALLY !

Priming the 8.3 is VERY easy. Front of the injector pump towards the engine is a bleeder, but doesn't look like a bleeder. Big nut with a smaller one inside of it. Loosen the center a couple turns, pump the hand primer till it comes out with NO air, tighten it up and it will fire right up. Usually takes me about 1 min to bleed one out that was run out of fuel.

- 26,246

- 1,193

- 113

- Location

- NY

2 hrs since your last post.

It certainly would not have taken 2 hours to read the TM and learn that you need to bleed the air out with the primer pump after changing the filters.

Sometimes, when you don't have time, you waste alot of time(yours and others).

Please consider using the TMs in the future. You aren't afraid to learn about your truck by trial and error. Reading the info we all gave you, is another great way to learn and in this case may have saved you a couple days time.

It certainly would not have taken 2 hours to read the TM and learn that you need to bleed the air out with the primer pump after changing the filters.

Sometimes, when you don't have time, you waste alot of time(yours and others).

Please consider using the TMs in the future. You aren't afraid to learn about your truck by trial and error. Reading the info we all gave you, is another great way to learn and in this case may have saved you a couple days time.

MontanaBighorn

New member

- 16

- 0

- 0

- Location

- MT

I fully intend to read the TMs as I intend to know this truck in and out. I repair commercial equipment (HVAC/R, food service, etc.) for a living and fully understand the value of proper technical documentation. In this case I'm just tinkering as I can. While two hours may have passed, that's not two hours spent working on the truck its more like 15 minutes here and then having to go work on something that pays me money and then coming back to it in which time hopefully I've gotten a response to my inquiry here.

With working seven days a week (self employed) I just haven't had the time to sit down and start reading yet but fully intend to this coming week as work usually slows down on Christmas day at least.

If there is any basic information available so that I'll at least understand what I'm reading in the TM it would certainly be appreciated. Do I understand correctly that diagrams and parts for the M939A2 series trucks also applies to the M923A2?

Anyways, I really appreciate the help and fully intend to pay it forward as my own knowledge increases.

With working seven days a week (self employed) I just haven't had the time to sit down and start reading yet but fully intend to this coming week as work usually slows down on Christmas day at least.

If there is any basic information available so that I'll at least understand what I'm reading in the TM it would certainly be appreciated. Do I understand correctly that diagrams and parts for the M939A2 series trucks also applies to the M923A2?

Anyways, I really appreciate the help and fully intend to pay it forward as my own knowledge increases.

- 3,754

- 1,539

- 113

- Location

- North Carolina - FINALLY !

Control "F" to search the TMs is your friend.

MontanaBighorn

New member

- 16

- 0

- 0

- Location

- MT

At this point I have replaced both fuel filters as well as drained and refilled the tank. Same issue. It looks like I'll be changing my lift pump, but will be waiting until I can either make room in my commercial shop or until it warms up a little. Since I'm going round and round with the local parts people trying to determine what the lift pump is anyway I'm not in a huge hurry. They tell me the part number has been changed several times and are uncertain which one I have. I don't want to try to drive the truck to them to inspect it because I don't want to risk having to be towed back home. When it warms up enough (eventually) I'll pull the pump and take it down there for them to match.

Thanks again one and all for all the assistance.

Thanks again one and all for all the assistance.

MontanaBighorn

New member

- 16

- 0

- 0

- Location

- MT

Yes, my local Cummins shop. He pulled up the part number and said it was changed and changed again and then discontinued best he could tell. In all fairness it's Christmas Eve and I'm sure he wanted to get home as badly as I did. Will try again in a few days.

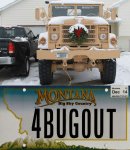

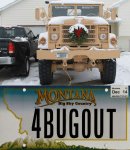

You guys have a very Merry Christmas! Monster-Beast is displaying its holiday cheer as well.

You guys have a very Merry Christmas! Monster-Beast is displaying its holiday cheer as well.

- 8,697

- 3,198

- 113

- Location

- Monrovia, Ca.

You need to troubleshoot it before throwing parts at it. Could be that "bleeder" that someone referred to earlier in this thread...it'is NOT a bleeder, it is the cap that holds the spring on top of the ball in the check valve. That valve could be you issue as well as taking air. Put a clear line between the outlet of the primary fuel filter and the fuel pump...not the lift pump...inlet, install a fitting so you can check the fuel pump galley pressure. No air should be in the clear line after the engine has run, the air will purge itself. Fuel pressure needs to be minimum 20 psi at idle and upwards of 30-35 at high idle. If it's not, change the check valve. If when trying to start after the clear line installation, the fuel bounces back and forth like being sucked back into the lift pump, the outlet check valve is failed in the lift pump, then it needs a new one, or a kit put into it. Give me an engine serial number, I can get you the correct p/n, or, give me the p/n the guy at Cumimins gave you and I can see if it's current.

- 3,754

- 1,539

- 113

- Location

- North Carolina - FINALLY !

Could be that "bleeder" that someone referred to earlier in this thread...it'is NOT a bleeder, it is the cap that holds the spring on top of the ball in the check valve.

You are absolutely wrong. Go look at TM 9-2320-272-23-2 WP 239, fuel system bleeding and priming. Items 6/7 ARE the bleeder for this pump. I have done this procedure a half dozen times.

- 12,195

- 329

- 0

- Location

- gainesville, ga.

ALL said and done, after the priming ect., I would say you are sucking air someplace, I would bet even after you throw a bunch of parts and money at your truck, you will still have the problem, FIND THE AIR LEAK

- 6,863

- 707

- 113

- Location

- Stratford/Connecticut

I got an extra fuel cap, drilled a hole and put a tire stem in it so I can pressure test my trucks fuel system with a few pounds of air.

- 114,254members

- 167,165threads

- 2,353,529posts

- 7,168online users