- 2,114

- 565

- 113

- Location

- Davis County, UT

I believe that I was told it was a brand new unit. And for the price (~$250 shipped), I sure hope it is. Though I'm not sure if I can trust my memory! Hah.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Was it a true Bendix AD-9 ? or a copy ? The copies are coming out of China and I'm not sure of their quality.I believe that I was told it was a brand new unit. And for the price (~$250 shipped), I sure hope it is. Though I'm not sure if I can trust my memory! Hah.

Well as long as they assembled it correctly it should be fine. Take the "spitter valve" apart and make sure there is a square 'O' ring on the piston.A copy unfortunately. Only an "AD-9 Style" air dryer.

To take the spitter valve apart, you must first find a 1/8" or 3/16" thick piece of steel a little over 1' wide. Put this in a vise tightly. Then set the valve on it aligning it up with the 2 notches on the piston (pics 3-4 ) . Then pushing down firmly on the valve use a 3/8" socket and remove the top bolt. To reassemble just reverse the procedure.

To take the spitter valve apart, you must first find a 1/8" or 3/16" thick piece of steel a little over 1' wide. Put this in a vise tightly. Then set the valve on it aligning it up with the 2 notches on the piston (pics 3-4 ) . Then pushing down firmly on the valve use a 3/8" socket and remove the top bolt. To reassemble just reverse the procedure.Finally pulled this off my air dryer. All 3 o-rings are there, but it is also covered in what appears to be dialectic grease too? I thought that was odd.

View attachment 576998 View attachment 576999 View attachment 576997 View attachment 576996

Thanks brianp454!I know this thread is a bit old, but I'm looking into this again.

Yes, it is common to use something like silicone grease in manufacturing for assembling o-rings. You just want to use a lubricant that is not the same base as the o-ring material as it will break the o-ring down in no time.

Did you ever get your issues worked out?

You're welcome!Thanks Valence! I’m trying to get some things sorted out myself.

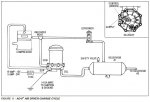

So for installing the AD-9, does anyone have a clear before and after set of schematics showing how to hook it up?

Ah, so you still had the brake switch on the brake fluid side?I’m working on installing this and the brake switch upgrade (moves the switch from the high pressure line to the brake pressure line for the trailer circuit). I got the switch kit from Erik’s (Brake Light Air Operated Switch Upgrade Kit For M35A2, 12255668 after my SECOND switch failed in a year. Sick of that crap!

So for installing the brake switch upgrade, does anyone have the TM or detailed setup for how to do so?

You might want to reconsider the plastic split-loom over the electrical pig-tail where it rubs against the frame; instead, take some old fuel/oil/air hose and cut it to slip over that spot to better prevent the frame from rubbing through. That plastic split-loom won't last long with the Deuce vibrations while driving.I've completed the new air brake hose routing to the air drier from the manifold. For added protection, I've covered each of the hoses in plastic split-loom.

There's actually two layers of split loom there, 3/8" and 1/2". But you're right, a piece of hose would provide better protection.You might want to reconsider the plastic split-loom over the electrical pig-tail where it rubs against the frame; instead, take some old fuel/oil/air hose and cut it to slip over that spot to better prevent the frame from rubbing through. That plastic split-loom won't last long with the Deuce vibrations while driving.

I only throw away old hoses if they are crumbling and falling apart as I hold them; instead, I keep them in a bin to use as insulation & protective wrap for other hoses/wire looms.

Rusty, I'm sorry I don't follow all of your connection description. I have plumbed the air dryer according to the instructions, as posted in Post #88, which definitely shows the dryer being placed before the air tanks and the only portion of the AD-9 connected to the governor is the "Control" line. I don't see it being of any help for the AD9 to run its delivery line over to the governor first then down to the air tanks. Are you saying this figure is wrong?First off the main line to the AD9 should be 1/2" not 3/8" line. It should come from your wet tank not straight from the compressor. Second the 1/4" line to the governor is pressure not vacuum. Did you use the same line (pressure hole) on the governor that should have come from the air tank to connect the AD9 to ? There should only be two lines coming off the governor. One should be from the AD9, and the second goes to the air-compressor. I can see from your photo you have the governor installed wrong. You must eliminate that old copper line and install the AD9 line to that plug. Second the air-compressor line should only be one line straight from the governor to air-compressor. The way it is installed now, everytime the AD9 burps it shuts-off the air-compressor for a moment. Then when the burp is over the air-compressor comes back on. The poor air-compressor is going crazy !!!