Wendell, good to hear from you .. sad news, but what a privilege to have meet the SGT at the parade ..I remember that he could still fit into his WWII Uniform and he wore it with great pride that day .. A true American Hero.

Appreciate the box find .. can you e-mail me at

mkoloc44@yahoo.com and let me know the particulars so we can get that shipped here for the HT

Zout, your project vehicle looks incredible .. glad to see that engine in place .. PB told me the engine that I picked up for you was a no go .. bummer, was hoping it was good .. at least the components on it were usable as the other engine that I donated from my 37 project proved to be usable even if it was bored out at one time .

OF Concur on the manufacture date WC vs M37 .. interesting fact regards the thrown rod/high RPM info .. might explain why so many of these engines have been bored out after being sold by Uncle Sugar.

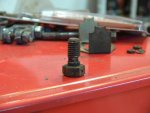

Started on my fuel system this week .. knew my tank had a couple of pinhole leaks after going thru the sandblast, so I yanked it and did some cleaning of the bad areas and soldered the holes up … hot water cleaned the tank at the local car-wash and then used Muratic acid to clean the interior ..couple of more rinces, and the tank looks like new .. Went thru the fuel pick-up unit, filter cleaned inside and out and new gasket and installed a NOS fuel sending unit. The filter material is interesting stuff on the fuel pickup unit in the tank and is the same material used in the fuel filter on the firewall.

Went thru all the fuel lines and the vapor lines from the front of the vehicle and the firewall fuel filter to the tank as I had gone thru the other lines during the engine rebuild .. used Acetone and air to do the final rinse and the lines came out clean as a whistle .. would have been a big mistake to have just soldered the tank and installed without cleaning the interior of the tank and the fuel lines as there was a build-up of old fuel gunk from sitting all those years and sediment in the tank.

Last part of this project before I paint and install was cleaning and priming the tank area underside of the M37. Wire brush, scraper, lots of elbow grease and then a wipe down cleaned the area nicely and it is now primed.

Yanked the rear fenders so that I can replace my welting and prime and paint that area when I paint the tank area …

Last week went thru the door hardware and window frames to include all of the mechanism and adjusted the door hinges. Window frames are primed and ready for paint .. Will paint when I do the tank and the underside of the M37. Have all new window sweeps, clips and door gaskets to install after paint.

Brakes are next.

and I will began soldering and crimping my wire ends after the holidays and my honeymoon

and I will began soldering and crimping my wire ends after the holidays and my honeymoon