Rellim4560

New member

- 14

- 0

- 0

- Location

- Tallahassee, Florida

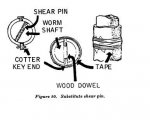

Ok I did something silly and need some help. I was winding the slack out of my winch cable after using it and ended up winding it to tight.  I pop the shear pin so there should be no damage to the winch but it pulled the chain end tight on the shackles. The problem seems to be now that there is tension on the winch the out side clutch is stuck in limbo and wont go in or out. I have new shear pin ordered and was wondering what to do when they get in.

I pop the shear pin so there should be no damage to the winch but it pulled the chain end tight on the shackles. The problem seems to be now that there is tension on the winch the out side clutch is stuck in limbo and wont go in or out. I have new shear pin ordered and was wondering what to do when they get in.

So far my thoughts are to cut a shackle with a torch and release the pressure and hope the winch lever will un-jam

or

Put a new shear pin in and see if i can loosen the tension by slipping the clutch with the winch in reverse.

Anyone have any suggestions or input.

So far my thoughts are to cut a shackle with a torch and release the pressure and hope the winch lever will un-jam

or

Put a new shear pin in and see if i can loosen the tension by slipping the clutch with the winch in reverse.

Anyone have any suggestions or input.

Attachments

-

74.8 KB Views: 251