kaiser2help

Member

- 182

- 3

- 18

- Location

- East Freetown, MA

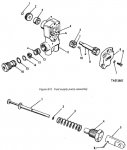

Has anyone ever taken apart their booster pump which is located on the side of the multi-fuel injector pump. The line from the primary filter goes directly into the pump directly through a plunger assembly. I fear before I have owned the truck someone incorrectly put the assembly together. I have tremendous fuel pressure right out of the tank. Just on the other side of the booster pump I have no pressure. I have a gauge installed in between the secondary filters and I am registering no pressure readings. I am positive that this releif assembly is probably put in wrong. And the TM'S show poor illustrations and not consistent pictures. If anyone has taken this apart before I need some guidance. Thanks.