I think the brake system is something like this - Air boost hydraulic system. Except there is only one booster unit. This is a blurb from the document:

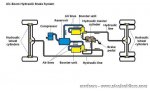

Air–Boost Hydraulic Brake System

(Air Brake Endorsement not Required)

An air–boost hydraulic brake system uses air pressure

to assist brake force. This is similar to vacuum–assisted

brakes on most passenger vehicles. An air–boost system

usually has the same components of a standard air

supply system including a compressor, governor, wet

and dry reservoirs. These components are found usually

in the same places as on a full air brake system.

The brake pedal linkage operates a hydraulic master

cylinder that sends hydraulic pressure to the booster

unit. Initially, at low pressure the hydraulic fluid passes

through the booster and begins to pressurize the wheel

cylinders moving the brake shoes out to the drums.

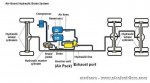

These booster units are similar in operation to

“Hypower” or “Hydrovac” vacuum boosters found

on most light and medium weight vehicles, but air

pressure is used to intensify the hydraulic pressure

generated by the master cylinder rather than vacuum.

Built into the booster unit is a hydraulically operated

air control valve.

This is where air from the reservoir is directed.

As the pressure from the master cylinder increases,

the air control section in the booster will open

and begin to deliver air pressure to the rear of the

air cylinder. The air cylinder pushrod transfers

pressure on a piston in the hydraulic section of the

booster, increasing the hydraulic pressure at the

wheel cylinders.

The driver has full control of the braking force as

the air control section modulates the boost pressure

in proportion to the master cylinder pressure.

If the vehicle was to lose all of the air pressure

the brake system would lose the air assist boost,

however the hydraulic system would continue to

work but at reduced effectiveness. An air brake

endorsement on a driver’s licence is not required

to operate a vehicle with this brake system. Consult

the operator’s manual for the vehicle you drive for

maintenance requirements.