peashooter

Well-known member

- 1,038

- 207

- 63

- Location

- Hanover, minnesota

POST 1~ SINGLE CIRCUIT BRAKE LINES

POST 2~ DUAL CIRCUIT BRAKE LINES

POST 3~ BRAKE PARTS REFERENCE GUIDE

POST 32~ BRAIDED STAINLESS FLEX LINES/HOSES

POST 40~ DUAL CIRCUIT MASTER CYLINDER BRACKET INFO & CAD FILE

SINGLE CIRCUIT BRAKE LINE INFO

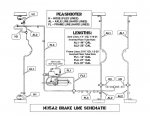

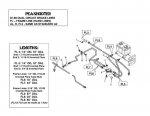

I've been selling Stainless Steel Braided Flex hose kits and Cunifer Hard line brake kits for a while now. I'd like to get away from making the hard line kits so figured I'd share my "secrets" with members so they can more easily make (or have made) their own lines. Attached is a cheat sheet that shows all the hydraulic brake lines on a M35A2 type truck. Many of the lines are the same on the late model dual circuit A2 trucks and A3 trucks as well (but not all).

The cheat sheet shows tube size, length, and fittings. **To my knowledge there is no info in the TMs regarding brake line lengths. I measured several truck's brake systems and took the average to come up with the listed lengths but they should all fit.

BRAKE LINE

I recommend using a high quality Cunifer (copper, nickel, iron) brake line as it will not rust, flares easily, and bends easily (by hand even). With Cunifer you should never have to worry about them again...ever. Cunifer will make install of the frame lines much easier also since you can easily bend it as you are installing it. The only 2 quality brands I know of are FedHill, and EziBend. ALL others will be a lower quality Cunifer that I would avoid as they are thinner, do not bend or flare as well, and are crack prone. AGS/Nicopp, JohnDow, and anything else that comes in a shrinkwrapped coil are going to be the inferior brands.

There is about 40' of hard brake line on a single circuit deuce. You might as well get a 25' coil of 1/4" tube, and 25' coil of 5/16" tube.

FLARING TOOLS & Hints

-Our trucks use SAE45 degree double flares (usually called Inverted Flares). Many auto parts stores will rent or loan out flaring tools (O'Reilley Auto has free loaners). If you want to spend more money on a nice setup, I like the turret style that is marketed under a few different names it makes a perfect flare very easily. Check out the Eastwood 25340 or Brakequip BQ351.

-Another handy tool is a Brake Tubing pliers and tubing bender (especially if you use steel brake tube). Check out Eastwood for these also (often cheaper on ebay).

-Also always use anti-seize on the tube nut threads and flare's bearing surface where the nut slides over to help prevent the tube from twisting when you tighten the nut.

-Make sure to get some type of plated steel tube nut. Stainless nuts are not as strong as steel and the threads will gall much easier.

SPRING ARMOR

Stainless Steel Spring Armor Wrap/Gravel Guard (like on the axle lines) can be found at summit racing in 20' lengths for around $30.

1/4" part number: GGS14S-20

5/16" Part number: GGS516S-20

DOT 5 Fluid

A good place to get inexpensive DOT 5 silicone brake fluid is from Iris Industries As of this posting, a gallon of it runs about $27, a case of 4 gallons shipped runs about $135. Unfortunately they do not take paypal or credit card (as of last time I ordered), so you need to mail a check in the old fashioned way.

Olga Iris Acevedo

Iris Industries Inc

46 Route 156 Suite#1

Yardville, NJ 08620

Tel: 609-228-3080

Cell: 609-972-2265

Email: Irisincorporated@aol.com

POST 2~ DUAL CIRCUIT BRAKE LINES

POST 3~ BRAKE PARTS REFERENCE GUIDE

POST 32~ BRAIDED STAINLESS FLEX LINES/HOSES

POST 40~ DUAL CIRCUIT MASTER CYLINDER BRACKET INFO & CAD FILE

SINGLE CIRCUIT BRAKE LINE INFO

I've been selling Stainless Steel Braided Flex hose kits and Cunifer Hard line brake kits for a while now. I'd like to get away from making the hard line kits so figured I'd share my "secrets" with members so they can more easily make (or have made) their own lines. Attached is a cheat sheet that shows all the hydraulic brake lines on a M35A2 type truck. Many of the lines are the same on the late model dual circuit A2 trucks and A3 trucks as well (but not all).

The cheat sheet shows tube size, length, and fittings. **To my knowledge there is no info in the TMs regarding brake line lengths. I measured several truck's brake systems and took the average to come up with the listed lengths but they should all fit.

BRAKE LINE

I recommend using a high quality Cunifer (copper, nickel, iron) brake line as it will not rust, flares easily, and bends easily (by hand even). With Cunifer you should never have to worry about them again...ever. Cunifer will make install of the frame lines much easier also since you can easily bend it as you are installing it. The only 2 quality brands I know of are FedHill, and EziBend. ALL others will be a lower quality Cunifer that I would avoid as they are thinner, do not bend or flare as well, and are crack prone. AGS/Nicopp, JohnDow, and anything else that comes in a shrinkwrapped coil are going to be the inferior brands.

There is about 40' of hard brake line on a single circuit deuce. You might as well get a 25' coil of 1/4" tube, and 25' coil of 5/16" tube.

FLARING TOOLS & Hints

-Our trucks use SAE45 degree double flares (usually called Inverted Flares). Many auto parts stores will rent or loan out flaring tools (O'Reilley Auto has free loaners). If you want to spend more money on a nice setup, I like the turret style that is marketed under a few different names it makes a perfect flare very easily. Check out the Eastwood 25340 or Brakequip BQ351.

-Another handy tool is a Brake Tubing pliers and tubing bender (especially if you use steel brake tube). Check out Eastwood for these also (often cheaper on ebay).

-Also always use anti-seize on the tube nut threads and flare's bearing surface where the nut slides over to help prevent the tube from twisting when you tighten the nut.

-Make sure to get some type of plated steel tube nut. Stainless nuts are not as strong as steel and the threads will gall much easier.

SPRING ARMOR

Stainless Steel Spring Armor Wrap/Gravel Guard (like on the axle lines) can be found at summit racing in 20' lengths for around $30.

1/4" part number: GGS14S-20

5/16" Part number: GGS516S-20

DOT 5 Fluid

A good place to get inexpensive DOT 5 silicone brake fluid is from Iris Industries As of this posting, a gallon of it runs about $27, a case of 4 gallons shipped runs about $135. Unfortunately they do not take paypal or credit card (as of last time I ordered), so you need to mail a check in the old fashioned way.

Olga Iris Acevedo

Iris Industries Inc

46 Route 156 Suite#1

Yardville, NJ 08620

Tel: 609-228-3080

Cell: 609-972-2265

Email: Irisincorporated@aol.com

Attachments

-

253.4 KB Views: 661

-

51.6 KB Views: 1,301

-

47.2 KB Views: 968

-

5 KB Views: 693

-

33.7 KB Views: 618

-

38.2 KB Views: 615

-

59.3 KB Views: 581

Last edited: