I can deal with the better than you crap and I should have never said your pressure gage on the fuel tank was silly. Myself the goat trails I have been on with my luck a branch would knock off the gage leaving a broken off peice of brass spilling fuel all over the tank and ground emptying my fuel tank while I said to myself that was a stupid place to put a gage. Well that's just me sad but true.

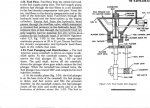

What crawled up your butt Floridianson ? Was I even talking to you ? As far as the pressure relief valve goes, the system I showed is basically like ours . It serves the same function. The relief valve does NOT open until 60 PSI, so it keeps the pressure in the system. All diesel systems that have mechanical injectors (not electronic rail systems ) will have this pressure relief valve in there fuel system. Read up on the fuel system before you go ranting at me.

As far as my sexual activity goes, I was a virgin until I got married, and have stayed faithful my whole life. I find your comments offensive. So if you cannot disprove what I have written then shut up and leave my personal life alone.

I'm sure I will get a reprimand for speaking out like this and you Floridianson will get nothing since you are such good buddies with the "elite" here, but I will speak my mind.

As far as my comments in my last post saying I will get flamed, if you read any of my past posts you will see I always get someone who says I'm totally wrong and until I prove it the flaming will continue. You yourself have been guilty of this. So in this post I was being proactive.

If it wasn't for the great ideas I have gotten for my deuce here I wouldn't waste my time with this site due to the attitude of some who think they are special, "The elite ! ". There are many on this site who have done really exceptional work on their trucks and others who have exceptional knowledge and I admire them for it . Peashooter, JasonS, Gringletaube (Gerhard) , Quadjumper, Warthog, Rayzor, Lt Dan, Silverstate, Brian454, many more that I cannot think of as I am very angry now. It is because of them I keep coming back. I used to think you where an upstanding guy Flordianson but after your post here I can see your true colors.