DeuceNewb

Member

- 397

- 6

- 18

- Location

- Wilmington, NC

***UPDATE:: Made it home finaly!!!

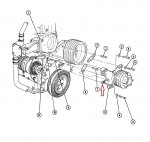

I'm in Maryland stuck on the side of the road because I lost the belt that drives the water pump in my 9series 5ton . I bought a new one from a napa down the road and cannot get it on! Just to be clear, the belt I bought has a part number 25-22425

I've read instructions online about how with the nhc250 you have to loosen the bolts around the water pump and rotate the pump itself to adjust belt tension. I cannot get it to budge. I got it loose enough that coolant was leaking out and yet could not get anything to budge.

Can somebody give me some clear instructions on what exactly needs to be moved in order to get a new belt on? What exactly is the part that turns.

I used twine to make a belt that got me to a gas station before tearing to shreds, and a longer belt from autozone that i got to go over both pullys won't turn the pump and just slides.

Lucky for me my aunt lives 45 min away and I just got to her house for the night, truck still at the gas station. I will be returning tomorrow morning to start again, and will end up removing the whole pump if i have to. If you are nearby to the intersection of route 32 and 1 (not too far from Ft Meade near baltimore) and could offer a hand It would be wonderful. I've still got to make it all the way back to north carolina.

I do have a smart phone so i can check this thread and read what has been posted or you can call me at 919-619-eight937 or my dad at 919-616-one774 if you have any tips on how to make it easy.

Also, any pics would be helpful in explaining exactly what i need to do

I'm in Maryland stuck on the side of the road because I lost the belt that drives the water pump in my 9series 5ton . I bought a new one from a napa down the road and cannot get it on! Just to be clear, the belt I bought has a part number 25-22425

I've read instructions online about how with the nhc250 you have to loosen the bolts around the water pump and rotate the pump itself to adjust belt tension. I cannot get it to budge. I got it loose enough that coolant was leaking out and yet could not get anything to budge.

Can somebody give me some clear instructions on what exactly needs to be moved in order to get a new belt on? What exactly is the part that turns.

I used twine to make a belt that got me to a gas station before tearing to shreds, and a longer belt from autozone that i got to go over both pullys won't turn the pump and just slides.

Lucky for me my aunt lives 45 min away and I just got to her house for the night, truck still at the gas station. I will be returning tomorrow morning to start again, and will end up removing the whole pump if i have to. If you are nearby to the intersection of route 32 and 1 (not too far from Ft Meade near baltimore) and could offer a hand It would be wonderful. I've still got to make it all the way back to north carolina.

I do have a smart phone so i can check this thread and read what has been posted or you can call me at 919-619-eight937 or my dad at 919-616-one774 if you have any tips on how to make it easy.

Also, any pics would be helpful in explaining exactly what i need to do

Last edited by a moderator: